Contract manufacturing

Skilled partner for subcontracting

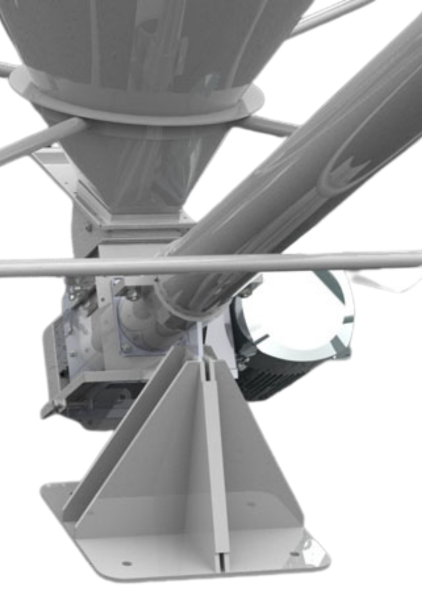

We offer our customers high-quality products and services with a flexible organisation and reliable delivery times. Our strengths are production expertise, experience, strong design capabilities, and excellent work quality.

Triotec's versatile and extensive machine base enables partners to offer various services. We implement both sub-assemblies and complete machines and equipment through subcontracting. Our special expertise includes laser-cut thin sheet parts and welded steel structures. Manufacturing occurs from start to finish in our facilities, including a wet paint shop and steel shot blasting. Efficient working methods and flexible organisation ensure reliable delivery times."

Product and service range

We offer our customers a flexible subcontracting partnership model. We can implement sheet metal work and steel structures according to customer specifications and also provide design services as part of the implementation.

MACHINE BASE

- Sheet metal centre FINNPOWER SG 6, max 6 mm, 1500 x 3000

- Sheet metal centre AMADA PEGA 244, max 5 mm, 1040 x 1000

- Sheet metal centre AMADA type VELA II, max 5 mm, 1270 x 1270

- Sheet cutter Hoan 4 mm / 3000 mm

- Laser press brake Promecam 1.2 m / 25tn 3 pcs

- Laser press brake Promecam 2.5 m / 65 tn CNC

- Laser press brake Promecam 3.0 m / 70 tn CNC

- Laser press brake Promecam 4.0 m / 200 tn CNC

- Band saw Amada 250 mm automatic

- Circular saw Kaltenbach 200 mm CNC

- Drill press 450/2000

- Milling machines 2 pcs

- Eccentric presses 20 tn, 30 tn, 90 tn

- Die cutting/punching machines 2 pcs

- Spot welding machines 2 pcs

- Mig welding machines 8 pcs

Other production capacity

- Shot blasting room 6 x 9 m

- Washing line 8 x 9 m

- Painting area 18 x 14 m

- Assembly area 9 x 14 m

Planning

We use the SolidWorks 2011 software for design. We accept the following 2D and 3D file formats:

- SolidWorks files 2009 and older versions

- DXF

- DWG

- Parasolid

- IGES

- Step

- ACIS

- STL

- ProE (part & assembly)

- Inventor (part)

- SolidEdge (part & assembly)