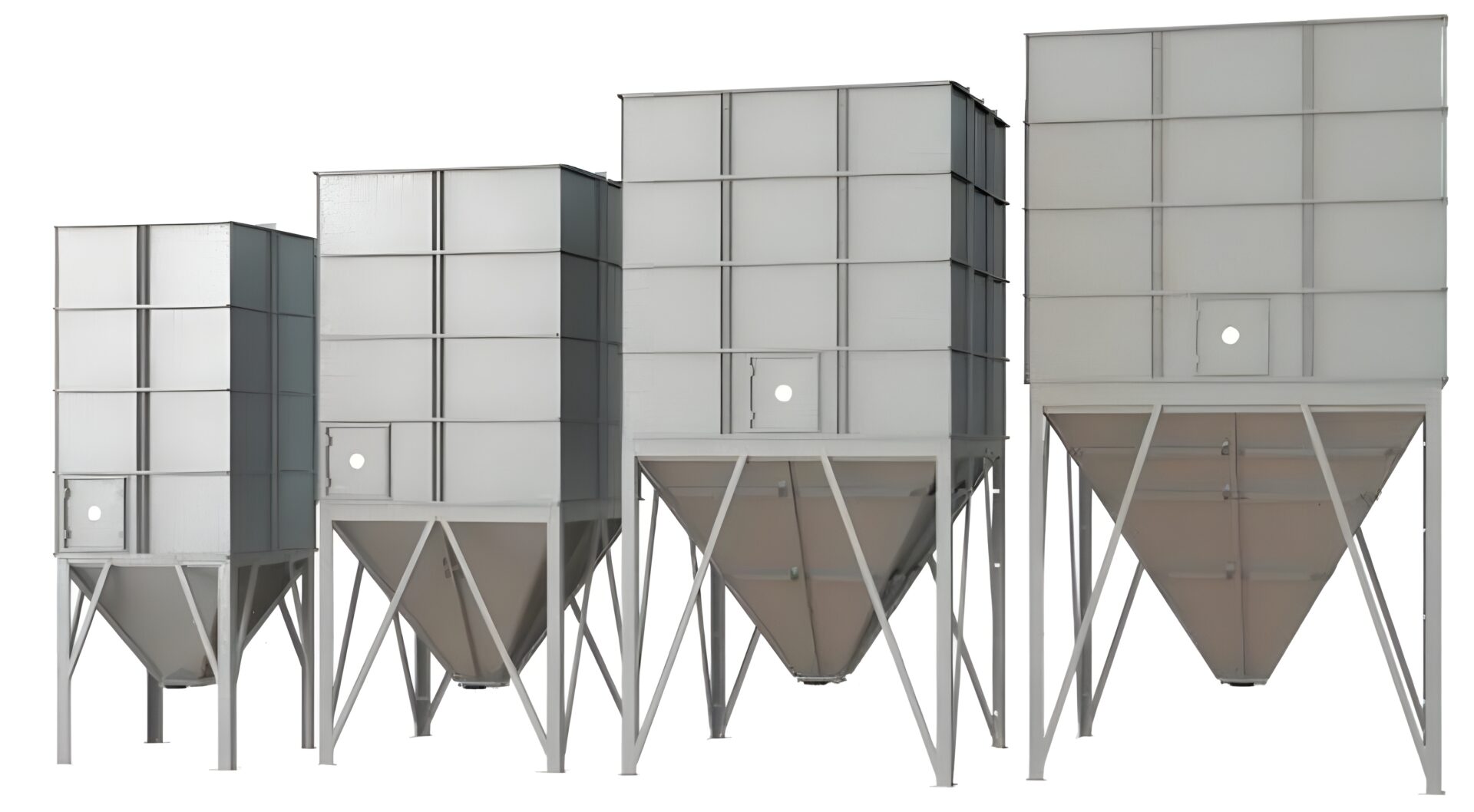

BM silos

With square silos, you can easily increase storage

capacity

Smooth-walled square silos with a conical bottom are designed for reliable, day-to-day storage of the same product. A smooth-walled silo is the perfect choice for storing grain, granular materials, feed powder, pellets, and other bulk products. Our silos can be customized precisely to your needs.

Modular silo

A modular silo is an ideal solution when handling free-flowing materials on a production line—whether it is for raw materials, intermediate storage, or finished product storage. The modular structure allows for a flexible solution to your storage needs.

Bottom cone

- The bottom cone is available in two different angles. The 45° cone is suitable for easily flowing materials.

- The discharge opening is 300x300 mm in size and has one shut-off slide.

- The 60° cone is ideal for materials with more challenging flow, such as feed and soybean meal mixtures.

- The discharge flange is 500x500 mm and has two shut-off slides, each measuring 250x500 mm.

Standard equipment

- Inspection hatch with window

- Manual shut-off slide

- Steel lid

Accessories

- Reinforced lid

- Safety railings

- Level sensors

- Weighing sensors with a display

- Vibrators

- Connection pieces for screw conveyors and feed system inlets

| dimensions mm | height m | volume m³ | Filling height | height m |

|---|---|---|---|---|

| 1050 x 1050 | 1,27 - 5,04 | 0,14 - 3,40 | 0,53 | 5-9,5 |

| 1300 x 1300 | 1,39 - 5,04 | 0,18 - 4,56 | 0,81 | 3,4-10 |

| 1550 x 1550 | 1,57 - 5,34 | 0,50 - 8,24 | 0,93 | 3,5-112 |

| 2050 x 2050 | 1,80 - 10,88 | 1,23 - 35,56 | 1,00 | 6-17 |

| 2550 x 2550 | 2,05 - 12,02 | 2,45 - 60,91 | 1,60 - 2,65 | 7-24 |

| 3000 x 3000 | 4,06 - 86,35 | 4,06 - 86,35 | 22 | 7-36,5 |

| 3546 x 3546 | 6,40 - 80,10 | 6,40 - 80,10 | 3,701 | 9,5-42 |

Clean series silos

Choose a Clean series silo when you want to change the type or color of the stored product, or if you want to ensure that the silo is completely clean after each use. This new generation silo is designed to meet various market needs, offering 100% efficient and optimized emptying without residues.

The Clean series silo is especially suitable for situations where cleanliness is important. It is ideal for versatile use with different products. The tank has no internal stiffeners. All bolts and nuts are installed outside, allowing for complete emptying and preventing foreign objects from interfering with material flow.

Bottom cone

The C-200, C-250, and C-300 models have 45° and 60° cones. The discharge flange is 300x300 mm for the 45° cone, and 500x500 mm for the 60° cone. The inspection hatch of the C-200, C-250, and C-300 models is located in the cone, which allows good access even when Clean series silos are side by side or in a group.

Galvanised parts & easy installation

Galvanized parts ensure long-lasting durability, good hygiene, and optimal silo emptying. The walls also withstand high-pressure washing. Installation in existing buildings is easy, as all silo parts fit through a standard-sized doorway. You can adjust their structure, choose stainless steel as the manufacturing material, or select painting according to your preferences.

Leg length

It allows the installation of most standard inlets and screw conveyors under the silo. Our range of extension legs allows the discharge height to be adjusted as needed.

Standard Equipment

- Clean series silos are delivered with a split steel lid, featuring a 415x415 mm square adapter plate. This allows easy connection to filling devices in the centre of the lid.

accesoires

- Reinforced lid

- Injection device with tank truck connection flange

- Cyclone and piping

- Safety railings

- Level sensors

- Weighing sensors with a display

- Vibrators

- Connection pieces for screw conveyors and feed system inlets

| Measurements mm | height m | capacity m³ | filling height | installation time Estimated hours (h) with 2 installers |

|---|---|---|---|---|

| 2125 x 2125 | 1,79 - 10,68 | 1,23 - 34,91 | 1,26 | 6-21 |

| 2711 x 2711 | 2,05 - 8,85 | 2,45 - 42,01 | 1,77 | 7-26 |

| 3147 x 3147 | 2,06 - 10,26 | 4,02 - 66,93 | 2,10-3,15 | 7-32 |

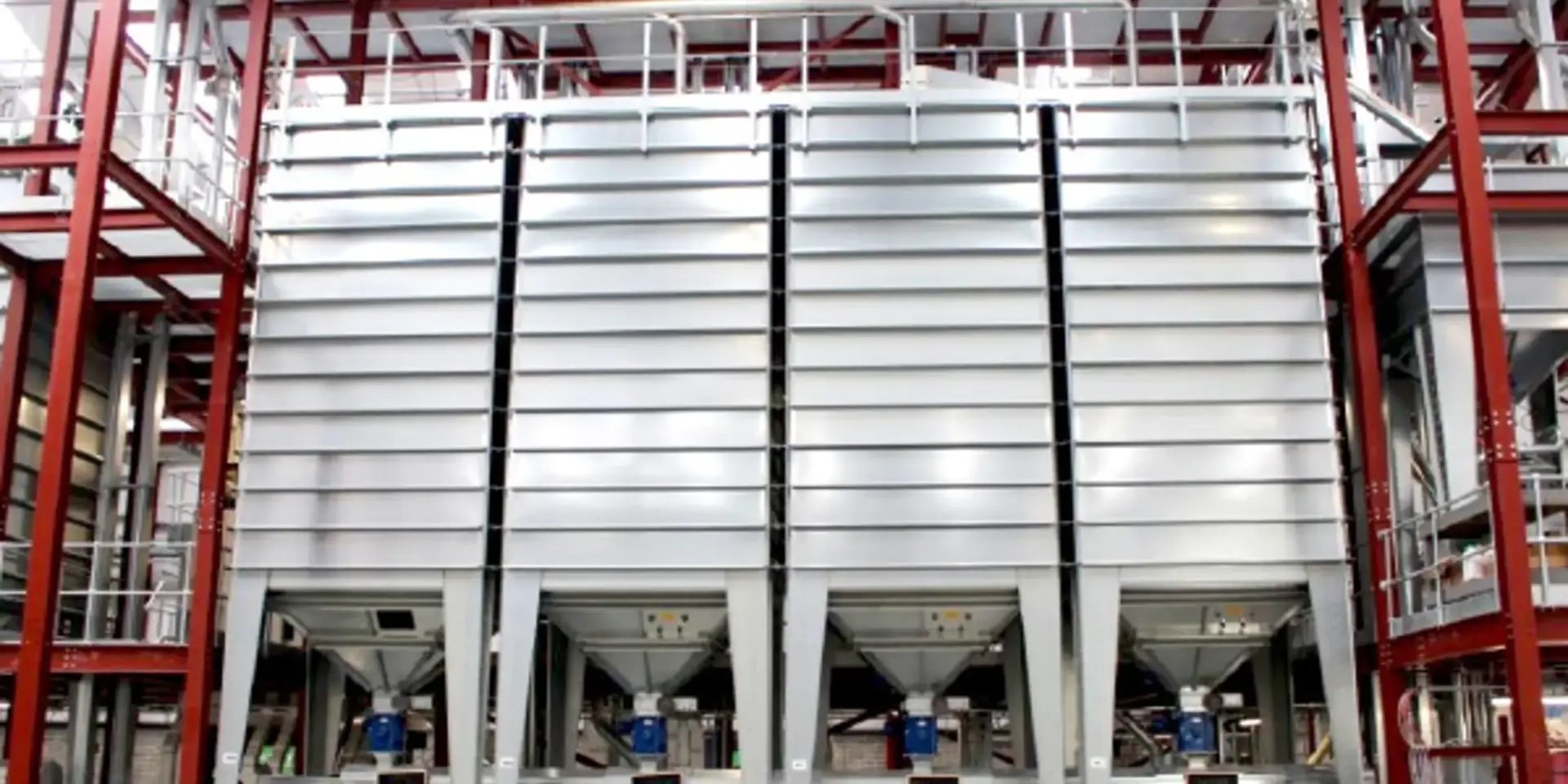

Modular silo for outdoor use

When there is limited space outside, choose a modular silo designed for outdoor use. The silo is often used with a staircase and walkway, which makes access to the silo easier.

It can serve as a raw material storage or as a discharge bin. The modular silo for outdoor use is the perfect choice for large-scale storage of dry materials such as wheat, barley, oats, feed meal, or pellets.

All side panels of the silo have external flanges with edges folded down, sealing the horizontal joints. The flanges and heavy-duty rubber sealing strips ensure the silo is completely tight.

Modular silos designed for outdoor use have a 45° roof

Standard equipment includes a 45° roof with an efficient cyclone and injection pipe. A rain cover protects the cyclone’s upper valve unit.

The silo is also available without injection equipment when filling is done using mechanical conveyor systems.

The bottom cone is available in two different angles. The 45° cone is designed for easily flowing materials. The discharge flange is 300x300 mm and has one shut-off slide. The 60° cone is ideal for materials with more challenging flow. The discharge flange is 500x500 mm and has two 250x500 mm shut-off slides.

By alternating the use of two discharge valves, you ensure that no old material is ever left in the silo.

standard equipment

- Injection pipe

- Injection connection flange

- Cyclone with rain cover or air pipe

- Inspection hatch with window

- Manual shut-off slide

- Expansion bolts for fastening to the base

| dimensions mm | height m | volume m³ | Filling height | installation time Estimated hours (h) with 2 installers: |

|---|---|---|---|---|

| 2550 x 2550 | 2.95 - 13.30 | 4.90 - 59.58 | 2,7 | 9,5-27,5 |

| 3000 x 3000 | 3.31 - 14.13 | 8.06 - 85.06 | 3,2 | 9,5-38 |