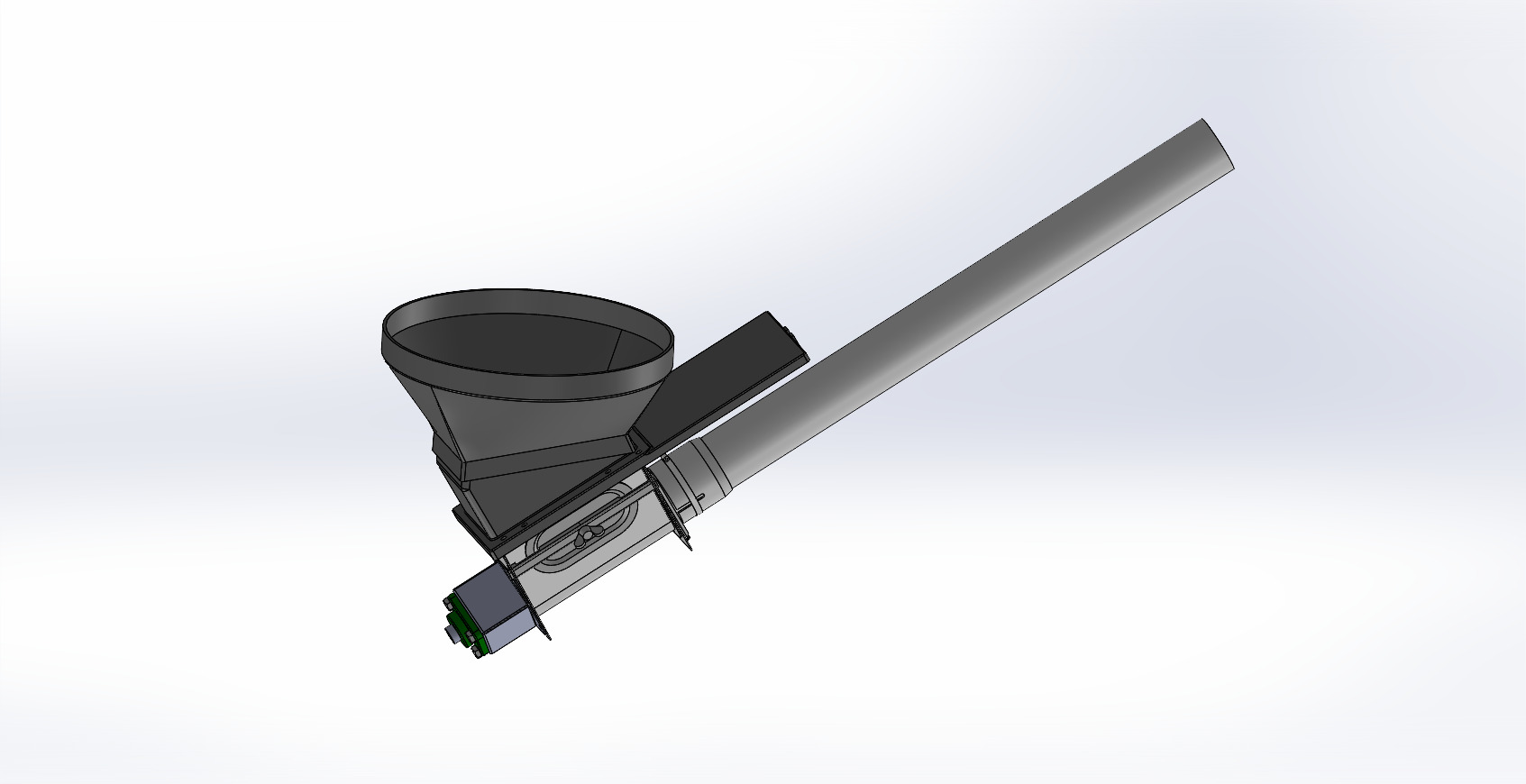

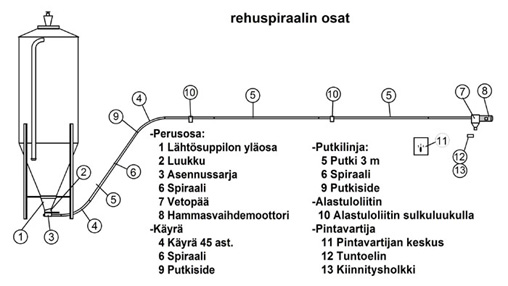

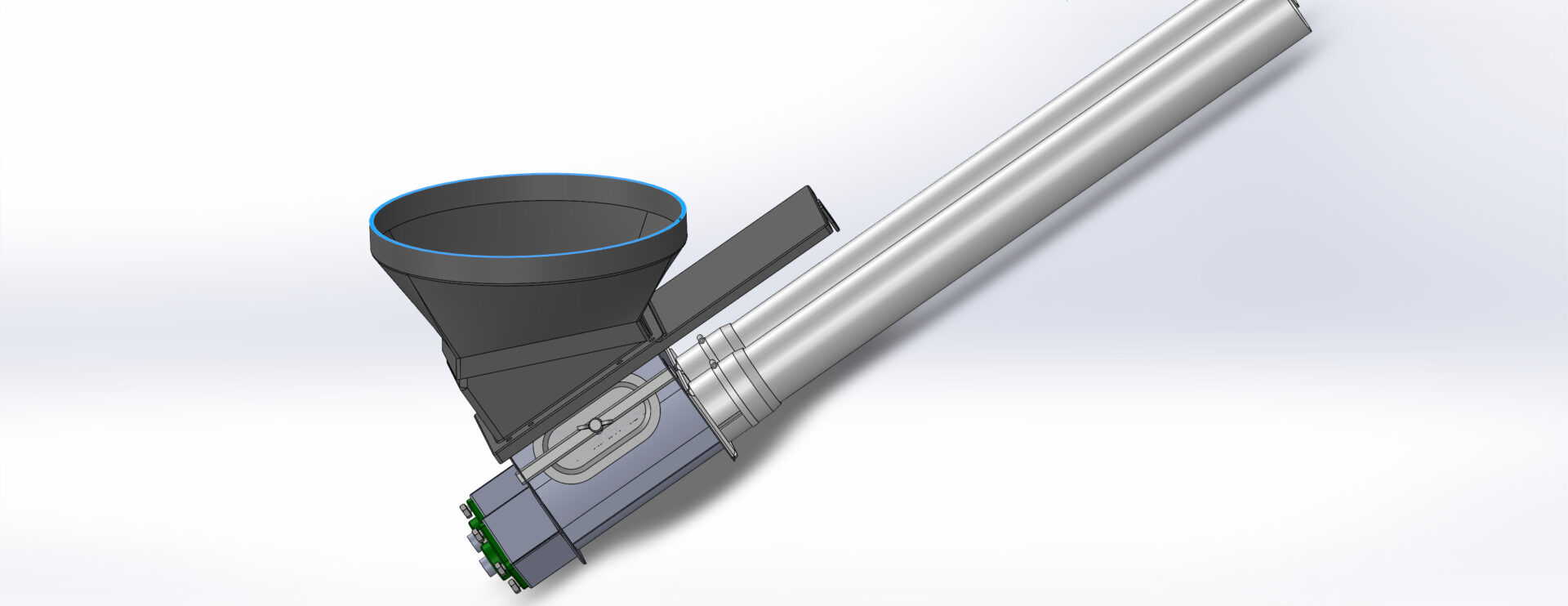

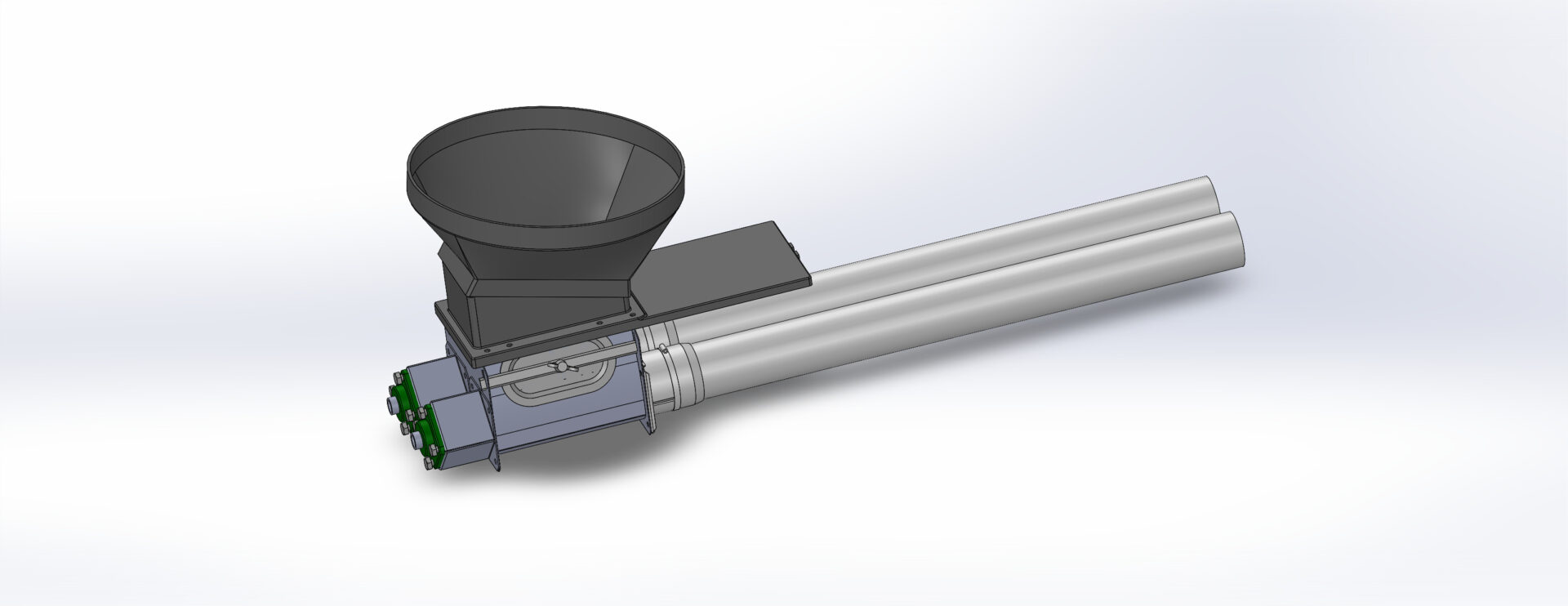

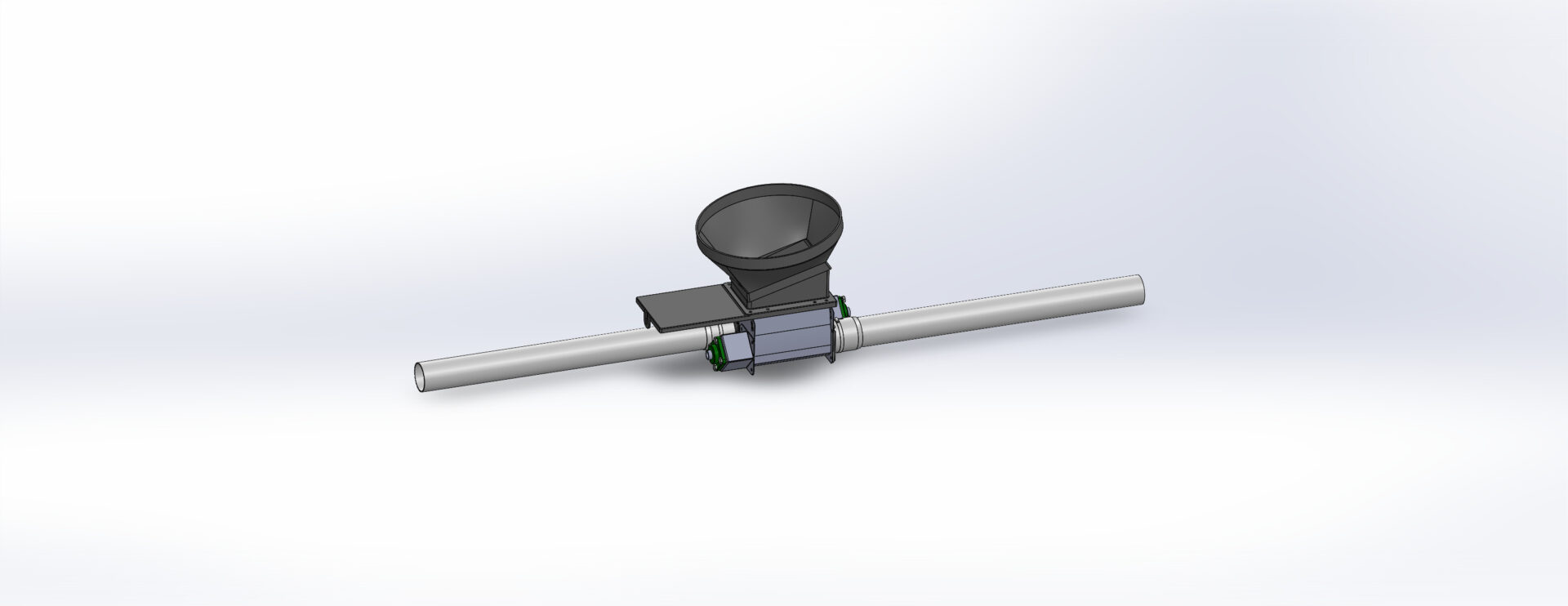

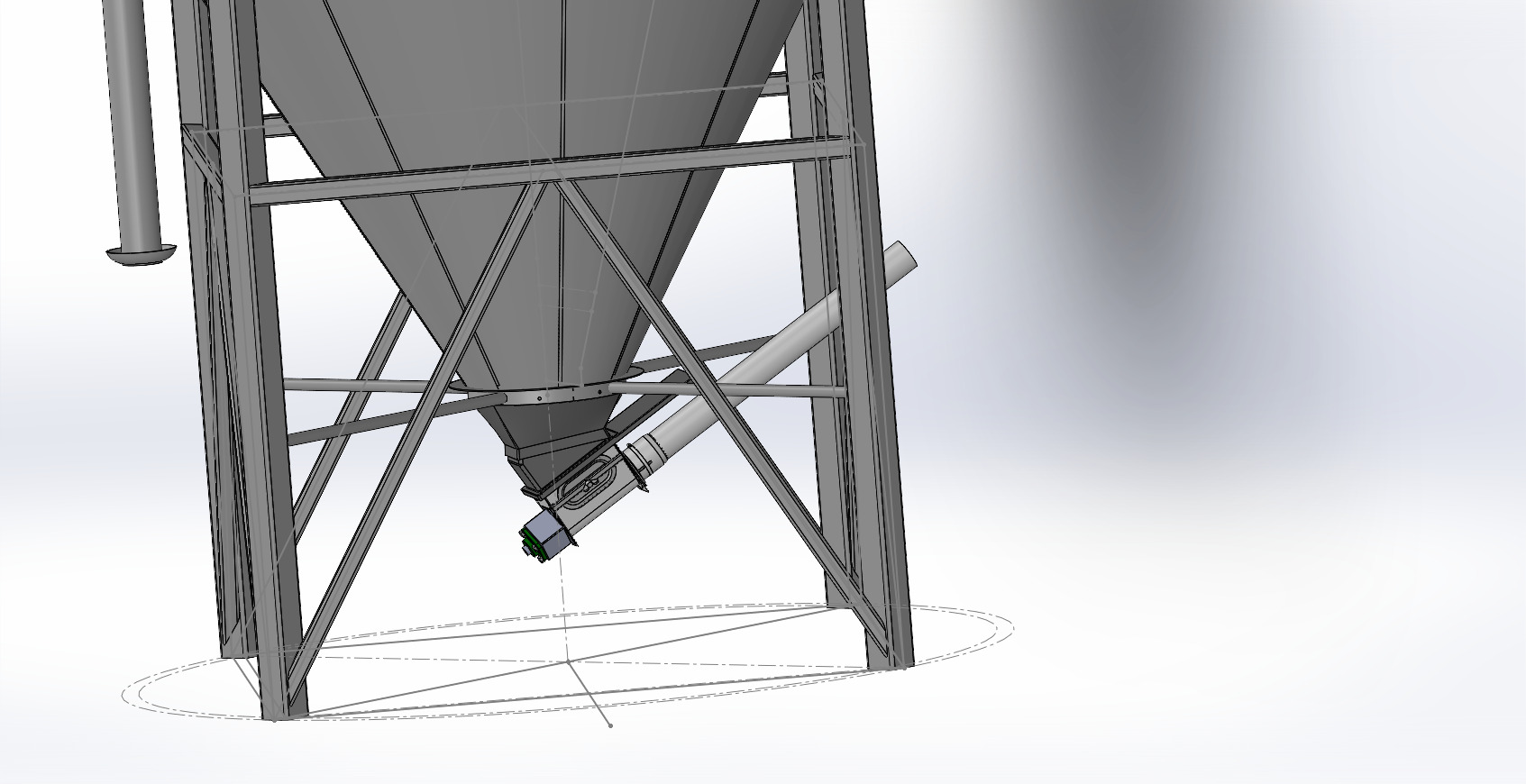

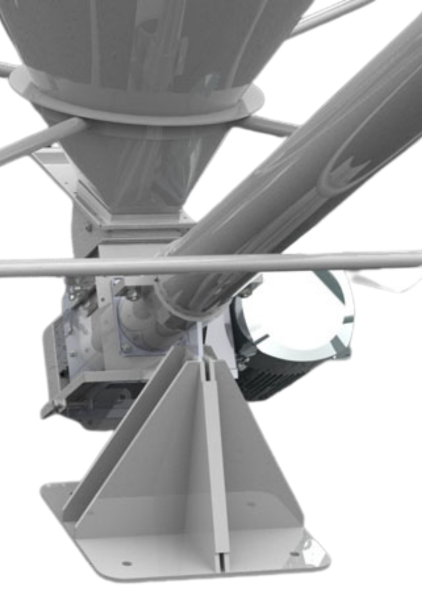

Single spiral outlet hopper

A shut-off slide is located below the upper part, and a service hatch is in the spiral’s outlet section, i.e., in the installation kit. By changing the position of the upper part and the hatch, the spiral can start at a 30° angle directly from under the silo.