Dries in demanding circumstances

Arska dryers are designed for northern conditions. They allow energy-efficient drying of very wet grain and maintain excellent quality.

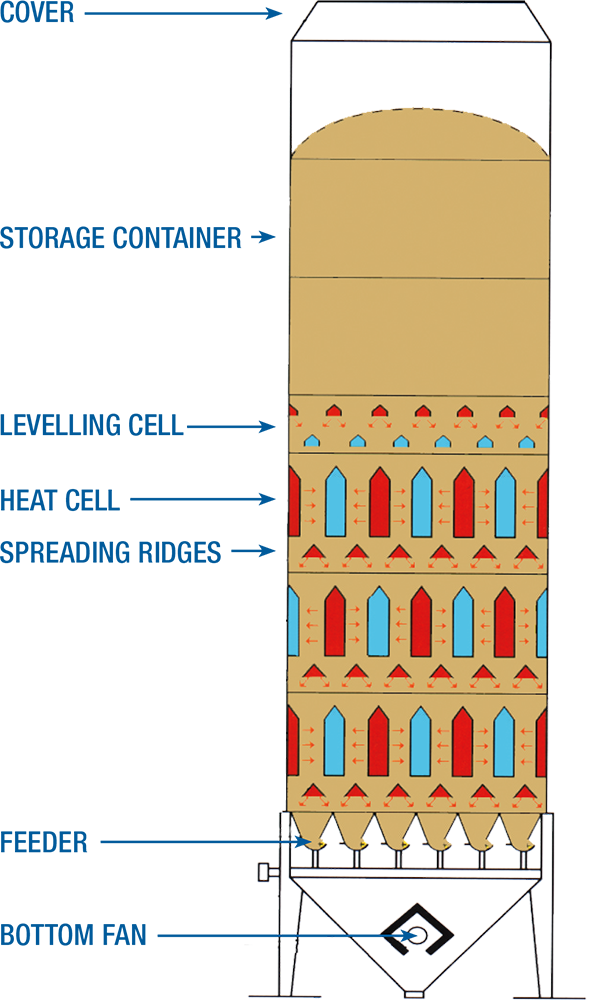

Designing the structures and details of the Arska dryers, minimizing the costs of drying and maximizing the quality of the outcome were the guiding design principles. The best features are hidden beneath the dryer´s surface and there are a lot of useful details to discover. Our solutions are the results of decades of experience and we develop them together with farmers based on their feedback.

Dries in demanding circumstances

Arska dryers are designed for northern conditions. They allow energy-efficient drying of very wet grain and maintain excellent quality.

Batch or continuous flow drying

In batch drying the grain moisture does not affect the end result. All Arska dryers are available as fast continuous flow dryers.

You decide the energy source

There are multiple energy options for Arska dryers. For example oil, gas or biofuels. Read more »

8 years

Heat exchangers

5 years

Grain dryers

5 years

Silos

5 years

Elevators

1 year

Electrical parts