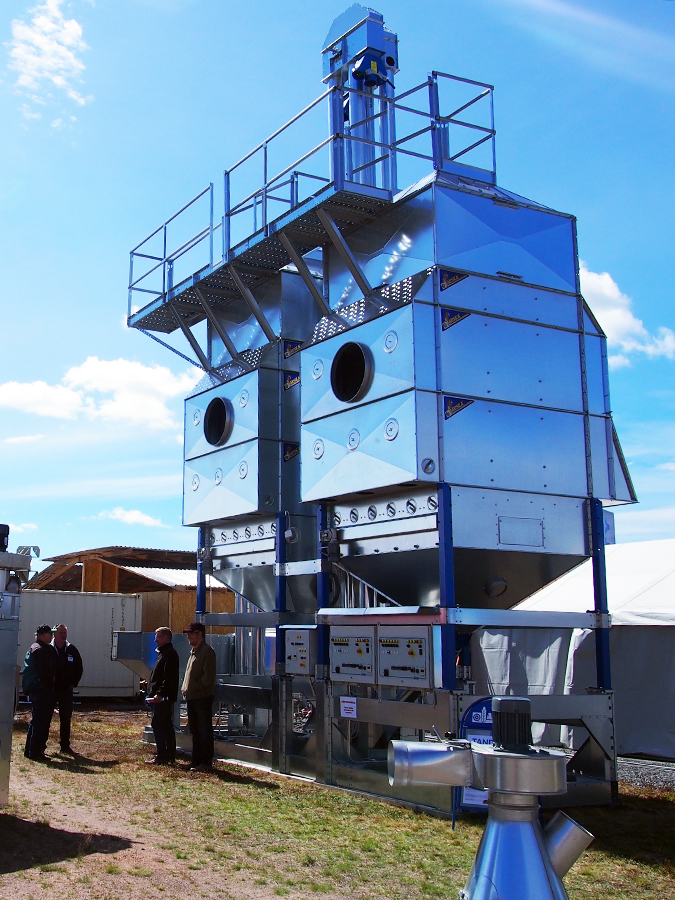

Tandem double dryers

Tandem combines two dryer machines with joint frames and heat source

A tandem double dryer has two dryers combined into one frame to create a dual batch dryer. The dryer operates with a 4-way divider which is connected to the heat source and the cooling fan. Grain dries in one dryer while the second is being cooled, emptied and refilled.

Both dryers have their elevators for recycling and discharging. For filling there’s a third elevator. The machinery consists of two Special models.

| Tandem | 2 x 2,5+3 | 2 X 3,5+3 | 2 X 4,5+4 |

|---|---|---|---|

| Capacity [t / h] | 7,8 | 9,4 | 12,6 |

| Total volume [m3] | 38,6 | 44,0 | 56,6 |

| Heat cell volume [m3] | 13,4 | 18,8 | 24,2 |

| Storage container volume [m3] | 21,6 | 21,6 | 28,8 |

| Dryer height [m] | 10,8 | 12,6 | 14,5 |

| Elevator min. height [m] / fill elevator min. height [m] | 11 / 13 | 12 / 14 | 14 / 16 |

| Elevator [model] * | A68 | A68 | A68 |

| Fuse size [A] * | 25 | 35 | 50 |

STANDARD EQUIPMENT

- 3 x elevator

- Overpressure heater, vacuum heater or EcoHeater bio heater

- Control panel

- 2 x pre-cleaner A200

- Tipping hopper 1x3m 1.5kW

- 2 x bottom fan 1.5kW

- Service platform and ladder

- Circulate piping

OPTIONS

- Rain cover for tipping hopper

- Seed Cleaner

- Cyclone

- GSM alarm

- Control automation

- Scale device

- Additional switch for feeder

- Rain covers for burner, elevator and pre-cleaner

- Motored shutter for heat cell

Fair warranties

8 years

Heat exchangers

5 years

Grain dryers

5 years

Silos

5 years

Elevators

1 year

Electrical parts