Intake hoppers

A wide range of intake hoppers

The Mepu range includes small and large hoppers to meet the needs of all customers. We offer drive-over hoppers, self-supporting hoppers equipped with chain conveyors, and traditional intake pits for dryer houses. The hoppers are assembled using bolted joints.

The chain conveyors and bucket elevators of Mepu hoppers are seamlessly compatible with Mepu dryers and other equipment. Owing to our wide product range, assembly of functional solutions excellent for grain handling is easy.

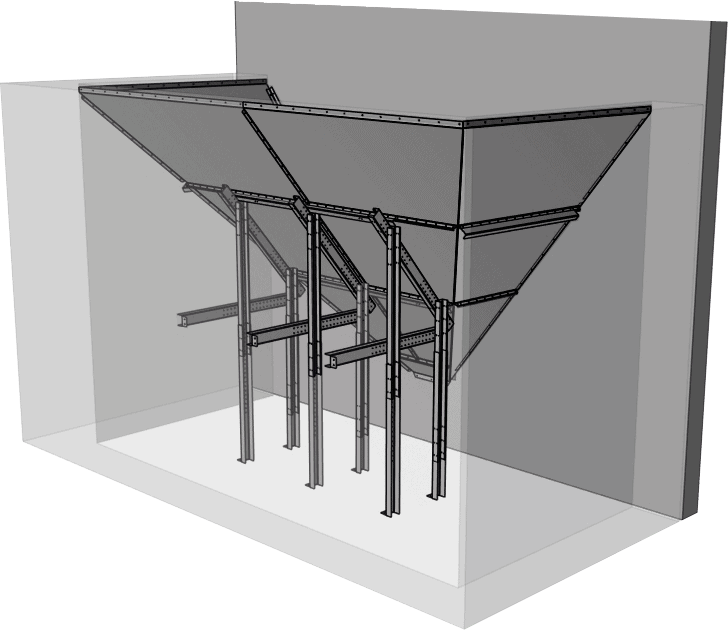

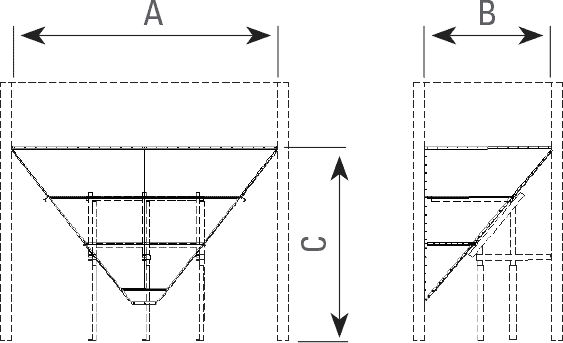

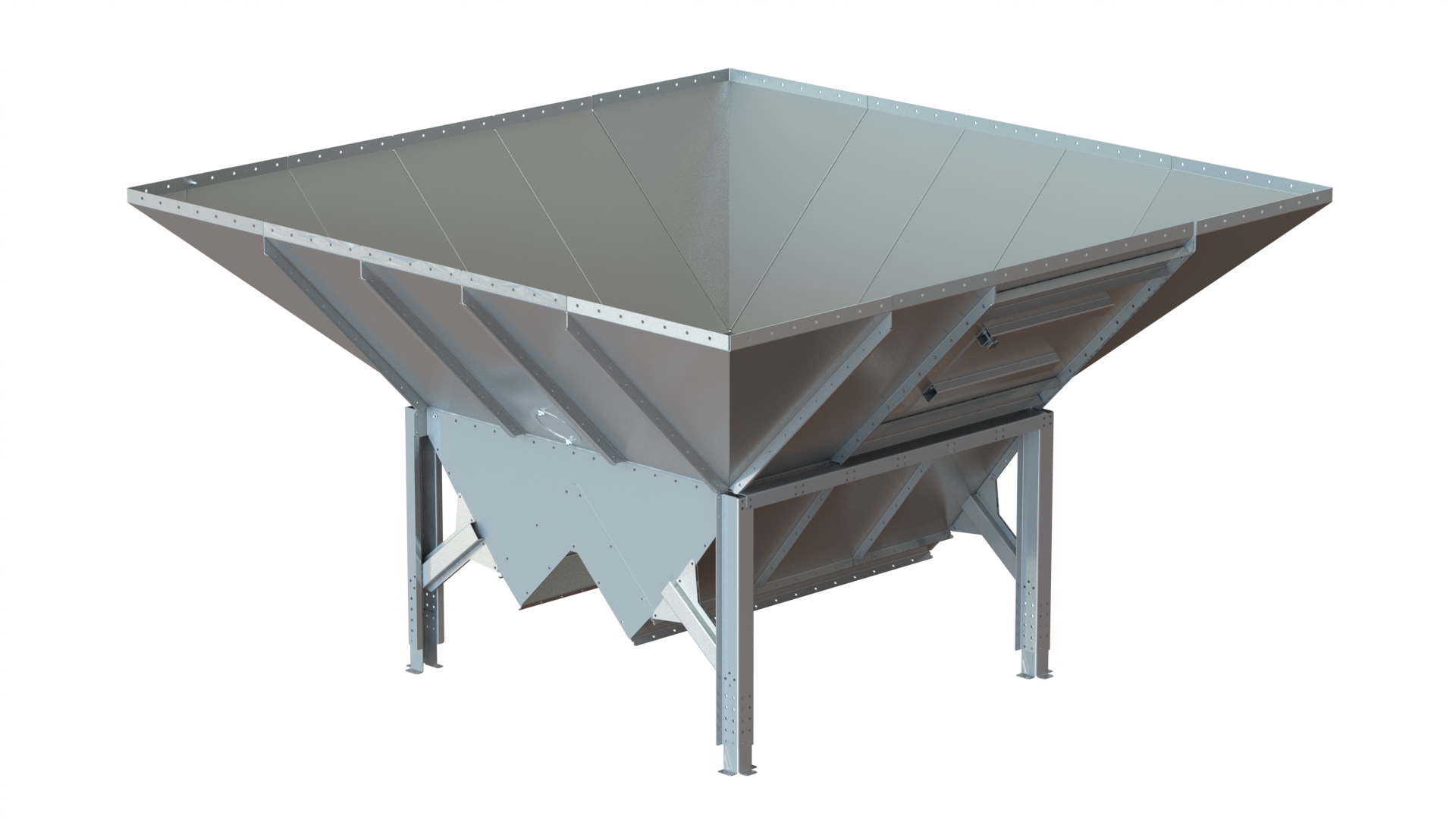

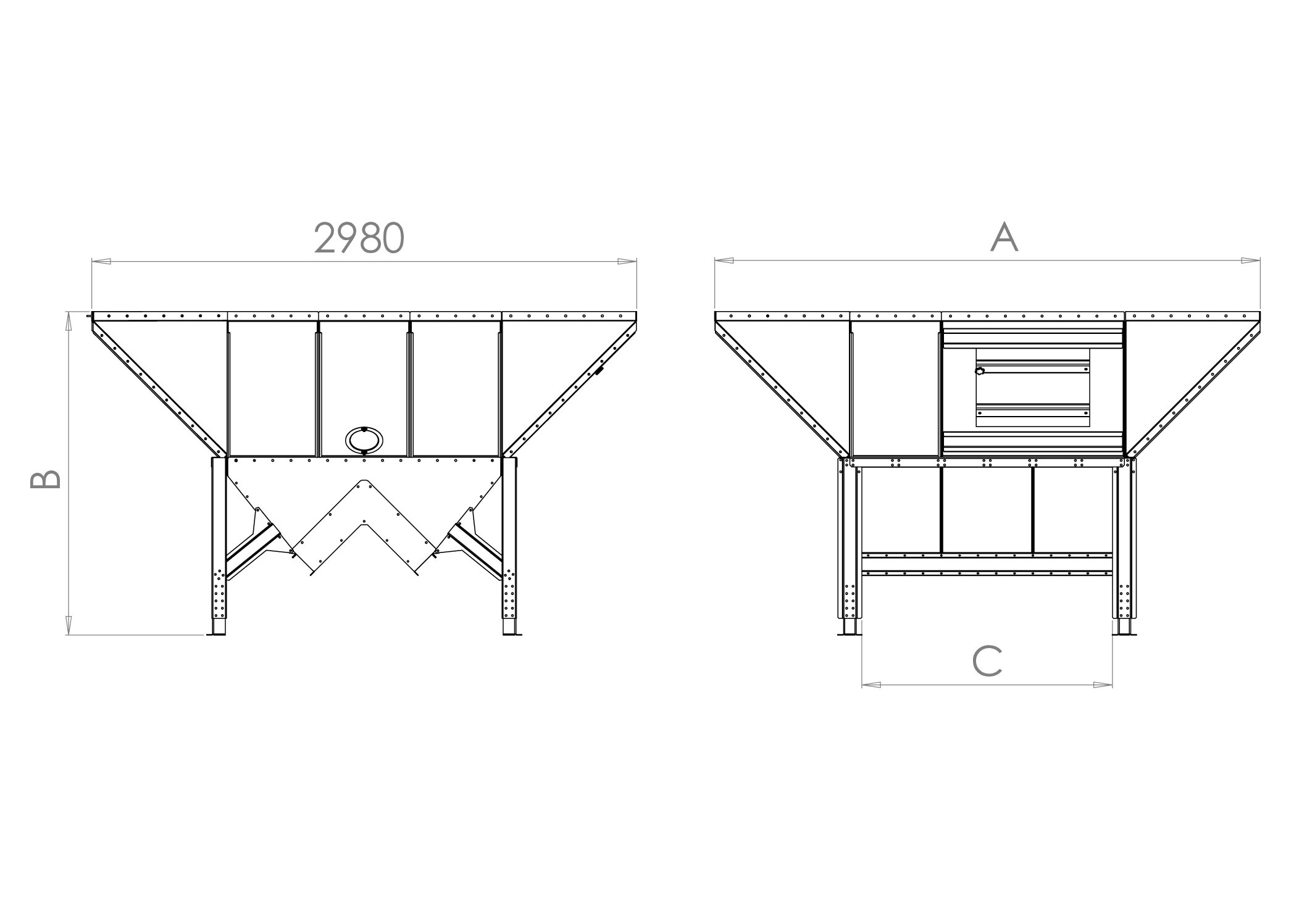

Intake pit

The simple and robust intake pit assembled inside concrete walls by bolted joints is good for dryer houses and mobile dryers equipped with a bucket elevator. The intake pit can be connected directly to the bucket elevator, in which case the grain flows by gravity.

Grates and support set assembled by bolted joints under the hopper are available as accessories.

| Model | A mm | B mm | C mm | m3 |

|---|---|---|---|---|

| 2 x 4 | 3 950 | 1 890 | 3 032 | 7,6 |

| 2 x 5 | 4 950 | 1 890 | 3 032 | 9,5 |

| 2,5 x 5 | 4 950 | 2 390 | 3 618 | 12,4 |

| 3 x 6 | 5 950 | 2 890 | 4 229 | 21 |

Low-intake hopper with chain conveyor

A hopper set assembled on level ground. The set includes a chain conveyor and the required elevator connection components. You can load a larger amount of grain into the hopper and the chain conveyor takes care of transporting the grain. The chain conveyor is chosen based on the bucket elevator’s performance. The hopper does not require additional support structures around it. The tipping height exceeds that of the lower options.

| model | A mm | B mm | C mm | D mm | m3 |

|---|---|---|---|---|---|

| KTG (60t) | 2 500 | 600 | 5 901 | 1 260 | 2 |

| KTG (60t) | 3 500 | 600 | 6 900 | 1 260 | 3 |

| KTIG 30-40 (80t) | 2 500 | 600 | 6 543 | 1 500 | 2,5 |

| KTIG 30-40 (80t) | 3 500 | 600 | 7 543 | 1 500 | 3,5 |

| KTIG 30-40 (100t) | 2 500 | 600 | 6 554 | 1 500 | 2,5 |

| KTIG 30-40 (100t) | 3 500 | 600 | 7 554 | 1 500 | 3,5 |

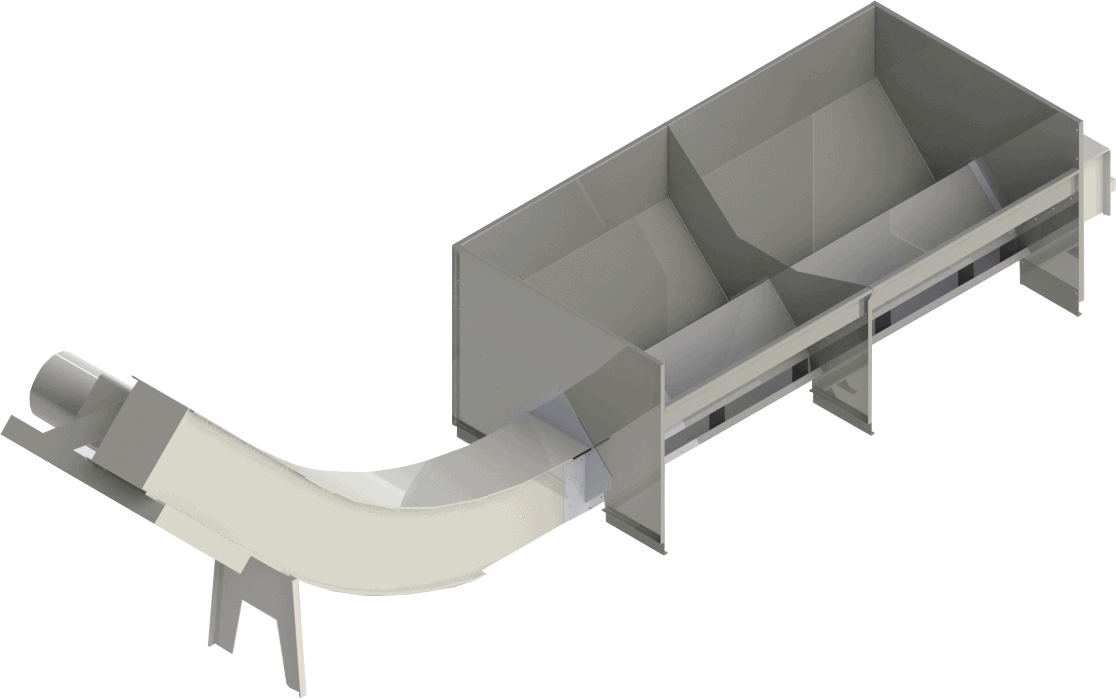

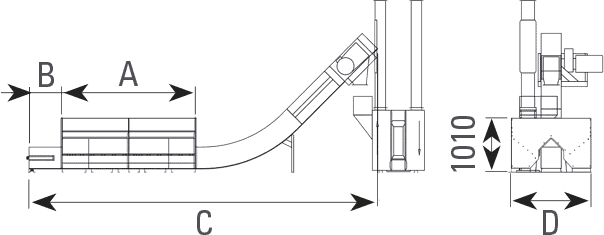

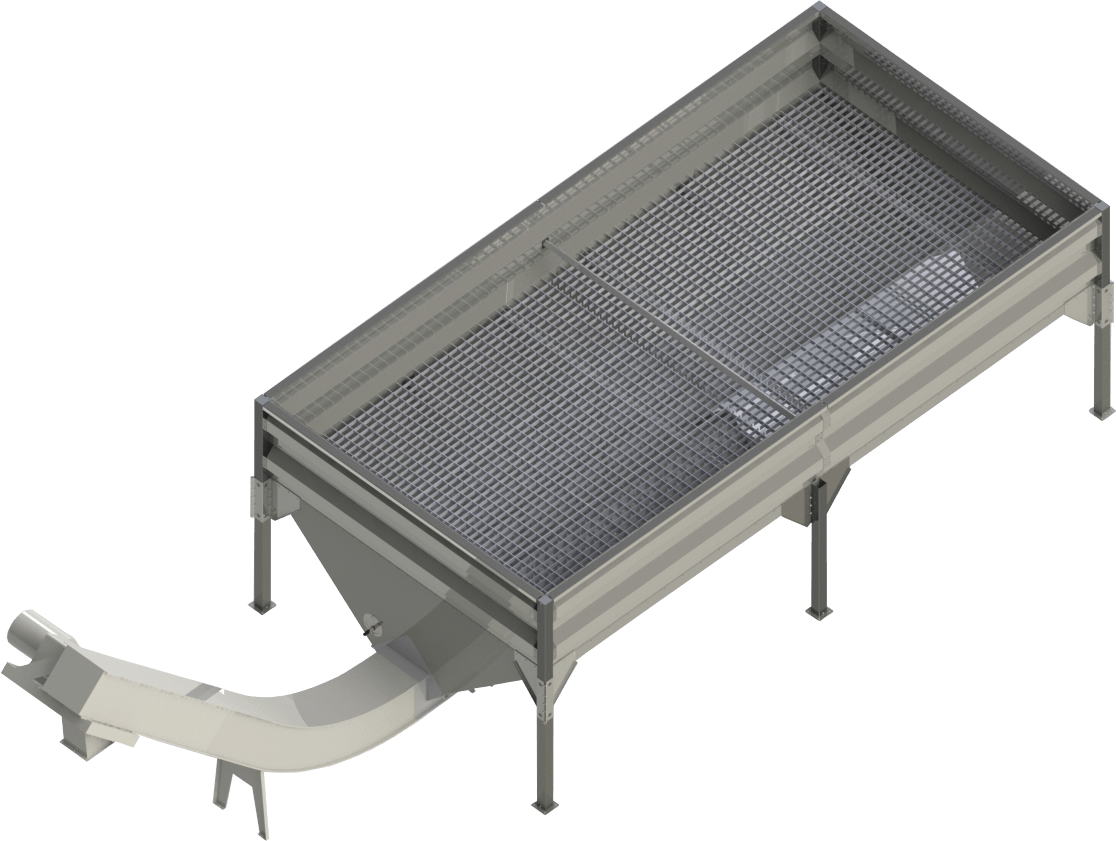

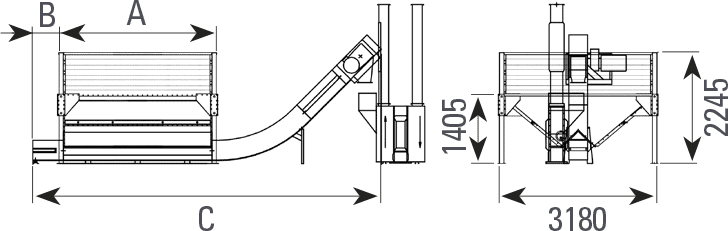

Intake hopper with chain conveyor

A low and light hopper quickly assembled on level ground, includes a chain conveyor and pivoted couplings for connection to the elevator. This means that the hopper can be positioned quite freely to the elevator. The chain conveyor is chosen based on the bucket elevator’s performance.

| model | A mm | B mm | C mm | m³ |

|---|---|---|---|---|

| KTG (60t) | 4 000 | 600 | 7 400 | 7 |

| KTG (60t) | 6 000 | 600 | 9 400 | 10 |

| KTG (60t) | 8 000 | 600 | 11 400 | 14 |

| KTIG 30-40 (80t) | 4 000 | 600 | 8 043 | 7 |

| KTIG 30-40 (80t) | 6 000 | 600 | 10 043 | 10 |

| KTIG 30-40 (80t) | 8 000 | 600 | 12 043 | 14 |

| KTIG 30-40 (100t) | 4 000 | 600 | 8 054 | 7 |

| KTIG 30-40 (100t) | 6 000 | 600 | 10 054 | 10 |

| KTIG 30-40 (100t) | 8 000 | 600 | 12 054 | 14 |

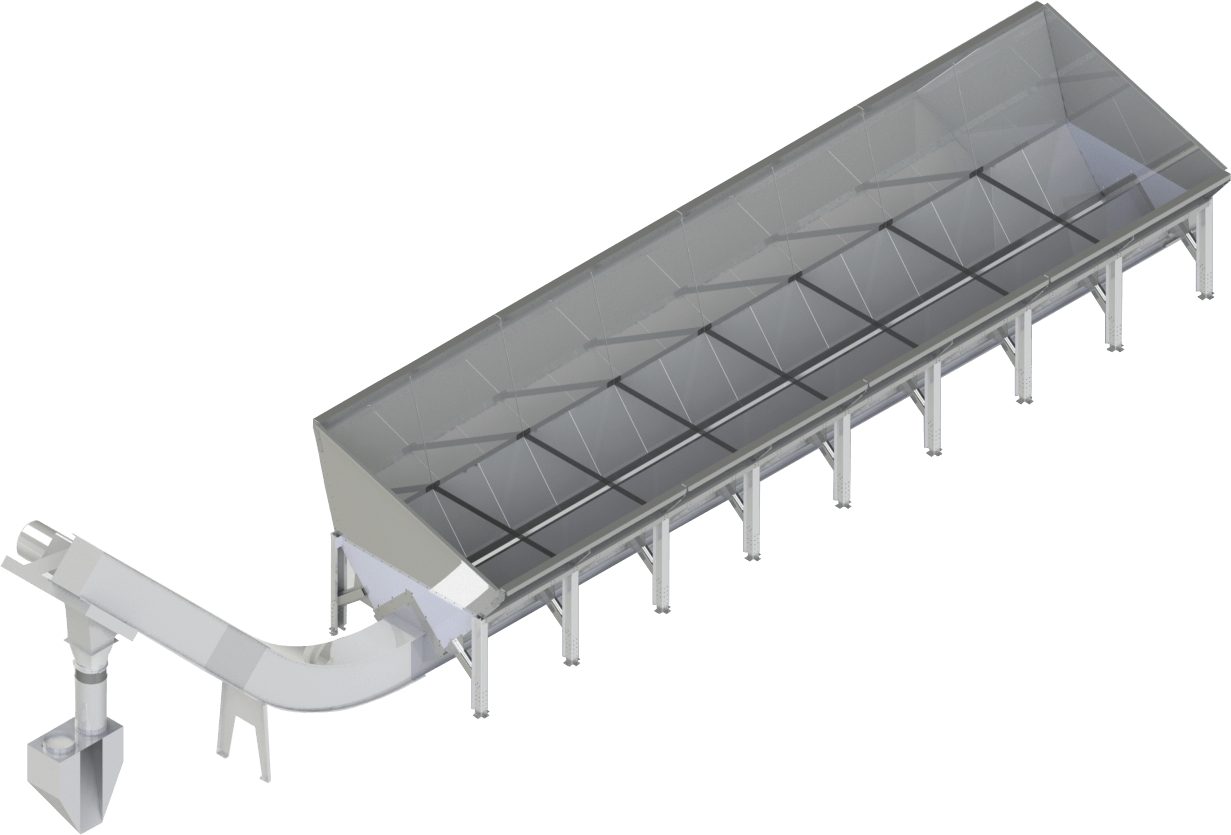

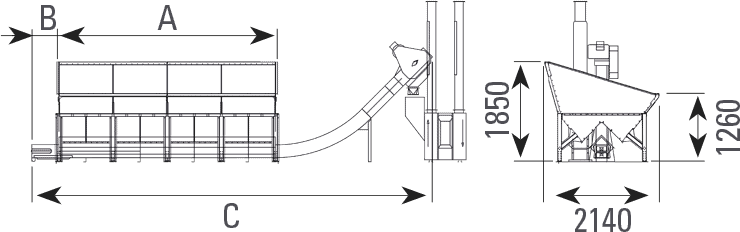

Large intake hopper with chain conveyor

A more robust version of the low Mepu hopper with the same features. Compatible with all dryers equipped with a bucket elevator. Owing to its great size, the hopper can also be used for grain storage.

For large intake hoppers (length 3180mm or 4270mm) there’s available steel canopy as an option! Canopy height can be increased with extra layers.

| model | A mm | B mm | C mm | m³ |

|---|---|---|---|---|

| KTG (60t) | 2 180 | 600 | 5 400 | 9 |

| KTG (60t) | 3 180 | 600 | 6 400 | 12 |

| KTG (60t) | 4 270 | 600 | 7 400 | 18 |

| KTIG 30-40 (80t) | 3 180 | 600 | 7 043 | 12 |

| KTIG 30-40 (80t) | 4 270 | 600 | 8 043 | 18 |

| KTIG 40-40 (100t) | 3 180 | 600 | 7 053 | 12 |

| KTIG 40-40 (100t) | 4 270 | 600 | 8 053 | 18 |

| KTIG 40-40 (100t) | 6 285 | 600 | 10 053 | 24 |

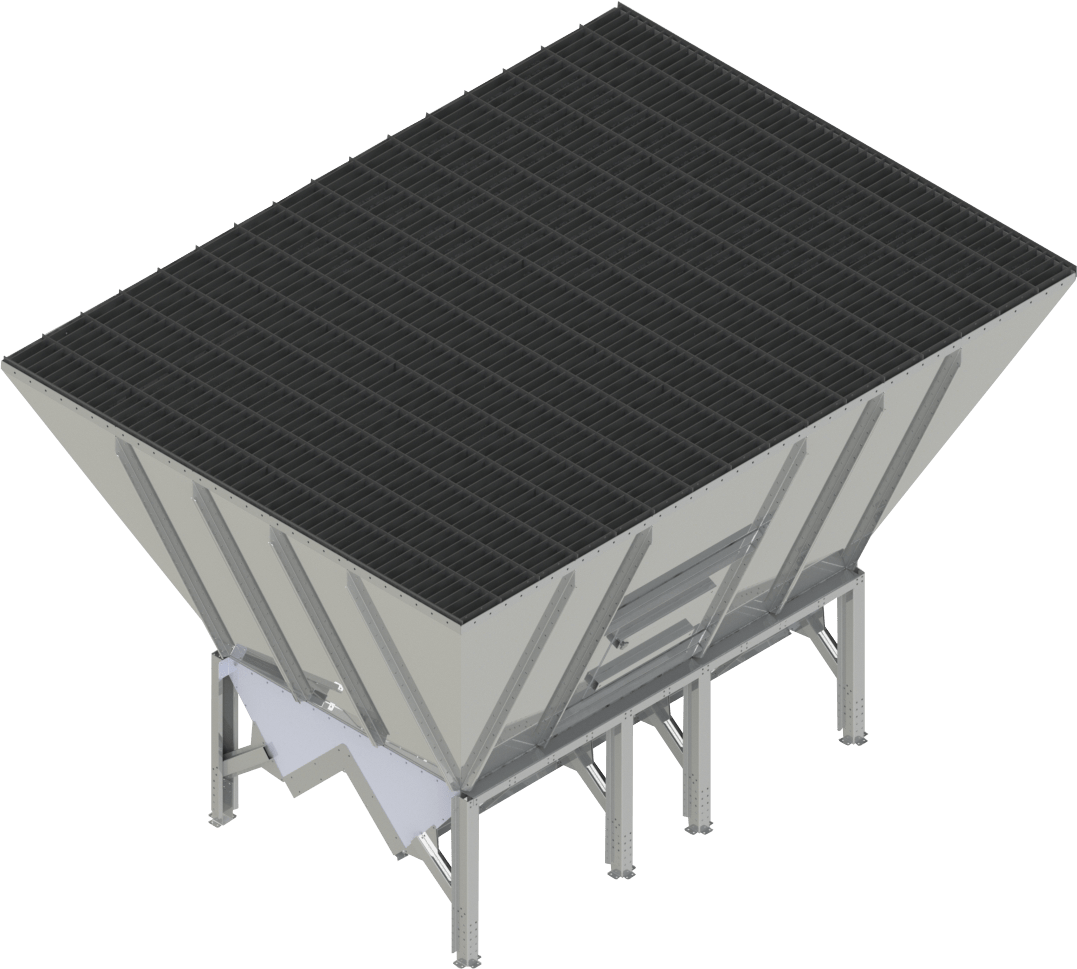

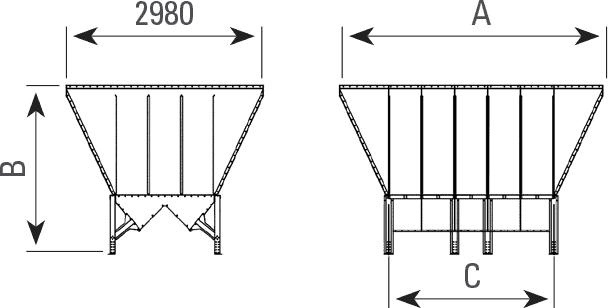

Intake hopper

Intake hopper assembled inside concrete walls and equipped with an efficient chain conveyor for applications that require a large grain reception capacity. The width of the drive-over hopper is always three metres; the length may vary between three and five metres (with 50cm increments).

The hopper is steep-sided and smooth-surfaced, which efficiently prevents arching. Cleaning of the hopper is easy owing to a manhole in the side wall.

The additional equipment available includes support beams for embedding in cast concrete and sturdy grates allowing driving over the hopper by tractor or truck. The chain conveyor is chosen based on the bucket elevator’s performance.

| Model | A mm | B mm | C mm | kg | m³ |

|---|---|---|---|---|---|

| KTG (60t) | 2 980 | 2 632 | 1 500 | 630 | 9,5 |

| KTG (60t) | 3 480 | 2 632 | 2 000 | 730 | 11,5 |

| KTG (60t) | 3 980 | 2 632 | 2 500 | 840 | 13,5 |

| KTG (60t) | 4 480 | 2 632 | 3 000 | 950 | 16 |

| KTG (60t) | 4 980 | 2 632 | 3 500 | 1 050 | 18 |

| KTIG 20-40 (60t) | 2 980 | 2 632 | 1 500 | 620 | 9,5 |

| KTIG 20-40 (60t) | 3 480 | 2 632 | 2 000 | 720 | 11,5 |

| KTIG 20-40 (60t) | 3 980 | 2 632 | 2 500 | 820 | 13,5 |

| KTIG 20-40 (60t) | 4 480 | 2 632 | 3 000 | 920 | 16 |

| KTIG 20-40 (60t) | 4 980 | 2 632 | 3 500 | 1 020 | 18 |

| KTIG 30-40 (80t) | 2 980 | 2 592 | 1 500 | 620 | 9,5 |

| KTIG 30-40 (80t) | 3 480 | 2 592 | 2 000 | 720 | 11,5 |

| KTIG 30-40 (80t) | 3 980 | 2 592 | 2 500 | 820 | 13,5 |

| KTIG 30-40 (80t) | 4 480 | 2 592 | 3 000 | 900 | 16 |

| KTIG 30-40 (80t) | 4 980 | 2 592 | 3 500 | 1 000 | 18 |

| KTIG 40-40 (100t) | 2 980 | 2 552 | 1 500 | 600 | 9,4 |

| KTIG 40-40 (100t) | 3 480 | 2 552 | 2 000 | 700 | 11,5 |

| KTIG 40-40 (100t) | 3 980 | 2 552 | 2 500 | 800 | 13,6 |

| KTIG 40-40 (100t) | 4 480 | 2 552 | 3 000 | 890 | 15,6 |

| KTIG 40-40 (100t) | 4 980 | 2 552 | 3 500 | 980 | 17,7 |

Intake hopper 45° for Conveyor (Low)

This intake hopper is meant for locations requiring high grain receiving capacity. It is built inside concrete walls.

The intake hopper has steep and smooth walls, effectively preventing bridging. The presence of a manhole on the side wall

makes cleaning the pour-over pit easy. The walls of the drive-over pit have a 45° casting angle, effectively preventing bridging.

The additional equipment available includes support beams for embedding in cast concrete and sturdy grates allowing driving over the hopper by tractor or truck. The product is compatible with the Skandia conveyor. The conveyor is sold separately.

| MODEL | A mm | B mm | C mm | kg | m³ |

|---|---|---|---|---|---|

| M30 KTG (60t) | 2 980 | 1 768 | 1 500 | 455 | 4,7 |

| M35 KTG (60t) | 3 480 | 1 768 | 2 000 | 555 | 5,8 |

| M40 KTG (60t) | 3 980 | 1 768 | 2 500 | 665 | 6,9 |

| M45 KTG (60t) | 4 480 | 1 768 | 3 000 | 775 | 8 |

| M50 KTG (60t) | 4 980 | 1 768 | 3 500 | 875 | 9,1 |

| M30 KTIG 20-40 (60t) | 2 980 | 1 768 | 1 500 | 445 | 4,7 |

| M35 KTIG 20-40 (60t) | 3 480 | 1 768 | 2 000 | 545 | 5,8 |

| M40 KTIG 20-40 (60t) | 3 980 | 1 768 | 2 500 | 645 | 6,9 |

| M45 KTIG 20-40 (60t) | 4 480 | 1 768 | 3 000 | 745 | 8 |

| M50 KTIG 20-40 (60t) | 4 980 | 1 768 | 3 500 | 845 | 9,1 |

| M30 KTIG 30-40 (80t) | 2 980 | 1 768 | 1 500 | 445 | 4,7 |

| M35 KTIG 30-40 (80t) | 3 480 | 1 768 | 2 000 | 545 | 5,8 |

| M40 KTIG 30-40 (80t) | 3 980 | 1 768 | 2 500 | 645 | 6,9 |

| M45 KTIG 30-40 (80t) | 4 480 | 1 768 | 3 000 | 725 | 8 |

| M50 KTIG 30-40 (80t) | 4 980 | 1 768 | 3 500 | 825 | 9,1 |

| M30 KTIG 40-40 (100t) | 2 980 | 1 768 | 1 500 | 425 | 4,7 |

| M35 KTIG 40-40 (100t) | 3 480 | 1 768 | 2 000 | 525 | 5,8 |

| M40 KTIG 40-40 (100t) | 3 980 | 1 768 | 2 500 | 625 | 6,9 |

| M45 KTIG 40-40 (100t) | 4 480 | 1 768 | 3 000 | 715 | 8 |

| M50 KTIG 40-40 (100t) | 4 980 | 1 768 | 3 500 | 805 | 9,1 |