Hopper bottom silos

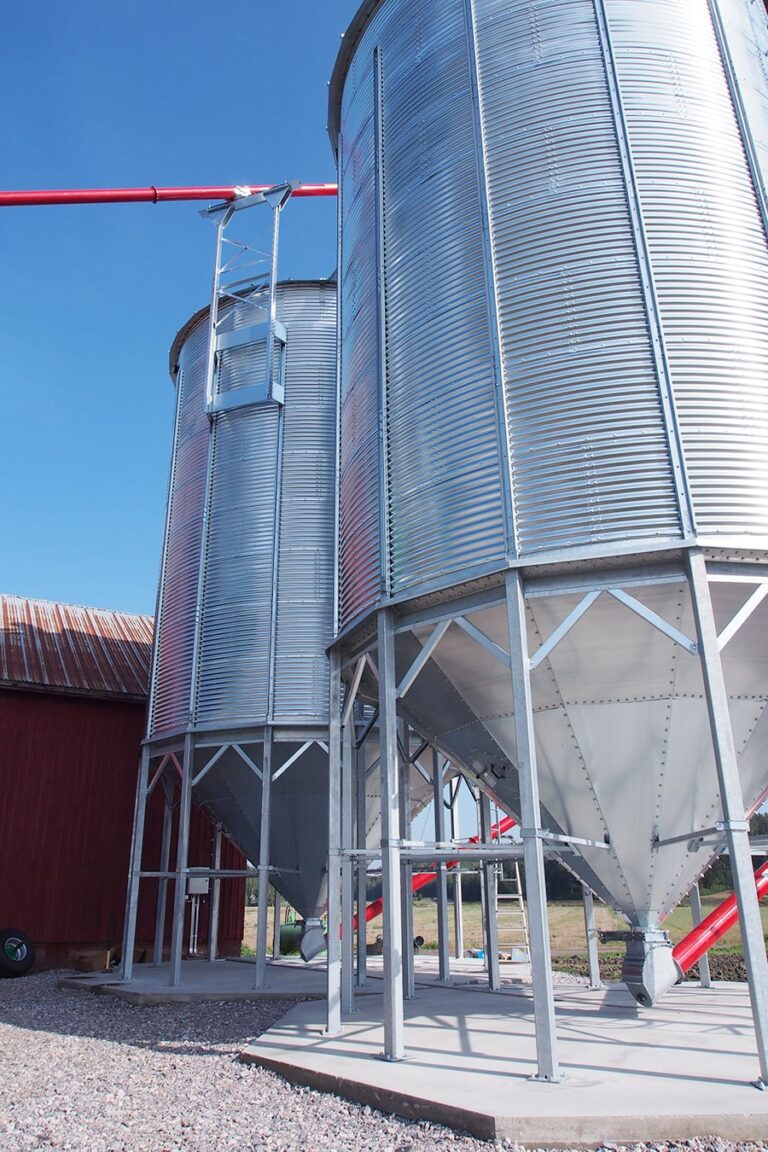

Mepu's hopper bottom grain silos are designed and tested to withstand the demanding conditions of the North. Featuring a 45° angle and 70cm of free space at the bottom, Mepu's hopper bottoms ensure complete emptying between grain batches. Our silos are engineered for minimal maintenance requirements.

The wall sheets and support steel are made from corrugated hot dipped galvanized steel. Wall sheet thickness ranges from 1.25 to 2.00 mm, with a galvanizing strength of 275g/m². For special conditions, we can provide silos with galvanizing strengths of up to 600g/m². The base is constructed from hot dipped galvanized steel in accordance with EN1090 standards. Mepu's hopper bottom grain silos are designed to meet Eurocode standards.

Our precise manufacturing ensures accurate shaping of the wall elements, allowing for easy and fast installation.

Ventilation systems can be installed in our hopper bottom silos, making them excellent for cooling dried grain. Emptying is facilitated by using either a Wheatheart auger with an adjustable inlet or a Skandia Elevators's bottom conveyor.

Advantages of Hopper Bottom SILO

+ Quick gravity-driven emptying

+ Keeps your grain cleaner

+ Ventilation system

+ Improves workplace safety and working conditions

+ Easy to maintain and clean

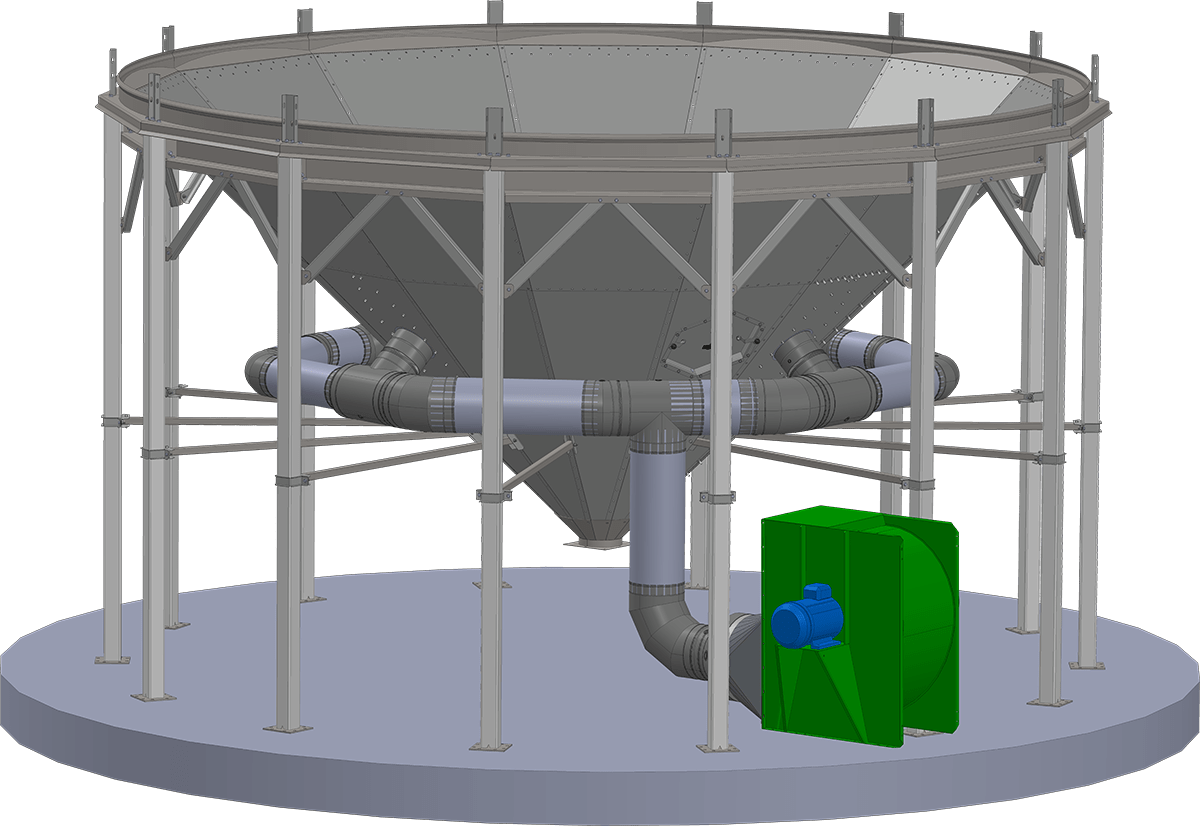

Ventilation system

Steel hopper bottom silos can be equipped with a ventilation system, in which case the silo is excellently usable for dry grain cooling. Grain can be stored in silos equipped with a ventilation system directly after threshing, which means that the silo can also be utilised for buffer storage.

| MODEL | vOLUME M3 | Ø M | WALL HEIGHT M | HEIGHT M |

|---|---|---|---|---|

| 480 / 4 | 81 | 4,8 | 6,20 | 7,40 |

| 480 / 5 | 96 | 4,8 | 7,03 | 8,23 |

| 480 / 6 | 111 | 4,8 | 7,85 | 9,05 |

| 480 / 7 | 127 | 4,8 | 8,68 | 9,88 |

| 480 / 8 | 142 | 4,8 | 9,50 | 10,70 |

| 480 / 9 | 157 | 4,8 | 10,33 | 11,53 |

| 480 / 10 | 172 | 4,8 | 11,15 | 12,35 |

| 480 / 11 | 187 | 4,8 | 11,98 | 13,18 |

| 480 / 12 | 202 | 4,8 | 12,80 | 14,00 |

| 480 / 13 | 217 | 4,8 | 13,63 | 14,83 |

| 480 / 14 | 232 | 4,8 | 14,45 | 15,65 |

| 560 / 4 | 116 | 5,6 | 6,63 | 8,03 |

| 560 / 5 | 137 | 5,6 | 7,46 | 8,86 |

| 560 / 6 | 157 | 5,6 | 8,28 | 9,68 |

| 560 / 7 | 177 | 5,6 | 9,11 | 10,51 |

| 560 / 8 | 198 | 5,6 | 9,93 | 11,33 |

| 560 / 9 | 218 | 5,6 | 10,76 | 12,16 |

| 560 / 10 | 239 | 5,6 | 11,58 | 12,98 |

| 560 / 11 | 259 | 5,6 | 12,41 | 13,81 |

| 560 / 12 | 280 | 5,6 | 13,23 | 14,63 |

| 560 / 13 | 300 | 5,6 | 14,06 | 15,46 |

| 560 / 14 | 321 | 5,6 | 14,88 | 16,28 |

| 640 / 4 | 159 | 6,4 | 7,03 | 8,63 |

| 640 / 5 | 186 | 6,4 | 7,86 | 9,46 |

| 640 / 6 | 212 | 6,4 | 8,68 | 10,28 |

| 640 / 7 | 239 | 6,4 | 9,51 | 11,11 |

| 640 / 8 | 266 | 6,4 | 10,33 | 11,93 |

| 640 / 9 | 292 | 6,4 | 11,16 | 12,76 |

| 640 / 10 | 319 | 6,4 | 11,98 | 13,58 |

| 640 / 11 | 346 | 6,4 | 12,81 | 14,41 |

| 640 / 12 | 373 | 6,4 | 13,63 | 15,23 |

| 640 / 13 | 399 | 6,4 | 14,46 | 16,06 |

| 640 / 14 | 426 | 6,4 | 15,28 | 16,88 |

| 720 / 6 | 275 | 7,2 | 9,18 | 10,98 |

| 720 / 7 | 309 | 7,2 | 10,01 | 11,81 |

| 720 / 8 | 342 | 7,2 | 10,83 | 12,63 |

| 720 / 9 | 376 | 7,2 | 11,66 | 13,46 |

| 720 / 10 | 410 | 7,2 | 12,48 | 14,28 |

| 720 / 11 | 444 | 7,2 | 13,31 | 15,11 |

| 720 / 12 | 478 | 7,2 | 14,13 | 15,93 |

| 720 / 13 | 511 | 7,2 | 14,96 | 16.76 |

| 720 / 14 | 545 | 7,2 | 15,78 | 17,58 |

Options

Wall support for conveyor

Conveyor support is attached to silo wall. It has a maximum load of 600kg and it’s height can be fine adjusted 6cm.

Catwalks

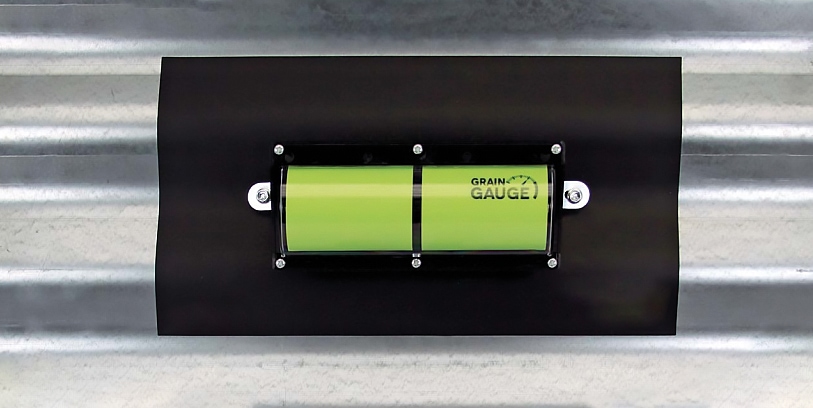

Grain level monitor

You can get a mechanic and maintenance free grain level monitor for silo. It’s proven and cost effective method to accurately monitor the levels of material in your silo. As the material in your silo reaches the grain level monitor, it turns the color from black to green – even glowing in the dark! You can install multiple level monitor devices along the silo wall at key levels.

Discharge augers and conveyors

There are different augers and conveyors available for silo discharging and grain transfer.