Flat bottom silos

Mepu offers a wide range of grain silos for farms. The flat-bottom silos of the Mepu product family provide a cost-effective solution for grain storage.

Our grain silos are constructed from high-quality Finnish steel, with material optimization incorporated into the product design. They can be safely erected using a crane.

Flat-bottom silos are constructed from corrugated hot-dip galvanized steel, with wall panels ranging in thickness from 1.25 to 2.00 mm and a hot-dip galvanizing strength of 275g/m². For special conditions, we can provide silos with galvanizing strengths of up to 600g/m². Our flat-bottom silos are designed to meet the requirements of the Eurocode standard, with various ventilation floor solutions available.

Emptying is facilitated by either a Wheatheart auger or a Skandia Elevator bottom conveyor. Additionally, a sweep augers expedites the emptying process and reduces the reliance on manual labor.

Advantages of Flat Bottom Silos

+ Cost-effectiveness

+ Ease of Installation

Discharge options for flat bottom silos

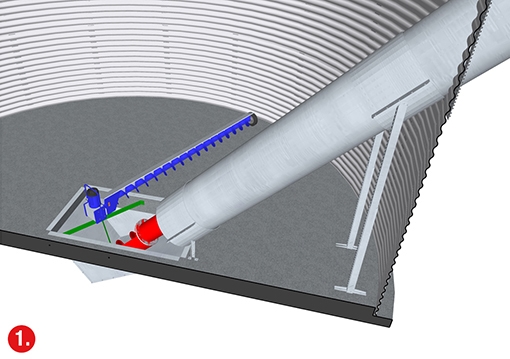

There are several ways to empty the Mepu silos. A flat-bottomed silo can be equipped with a movable sweep auger (1) in conjunction with a pulling Wheatheart screw auger. Sweep auger’s maximum capacity is 25t / h.

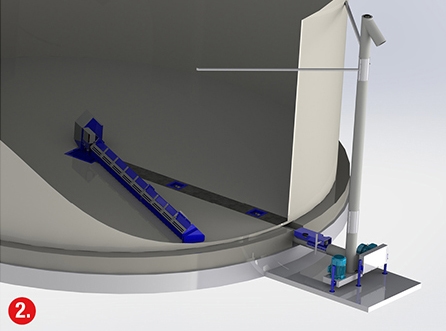

Another option to empty a flat bottom silo is a stationary sweep auger (2) that transfers the grain to the horizontal discharge screw and then to the discharge end. Three different versions can be selected for the discharge head: horizontal, with 25 degree angle and vertical (in the picture). Discharge screw’s maximum capacity is 80t / h.

| Model | volume (m3) | Ø (M) | wall height (M) | height (M) |

|---|---|---|---|---|

| 480 / 4 | 68 | 4,8 | 3,30 | 4,50 |

| 480 / 5 | 83 | 4,8 | 4,13 | 5,33 |

| 480 / 6 | 98 | 4,8 | 4,95 | 6,15 |

| 480 / 7 | 113 | 4,8 | 5,78 | 6,98 |

| 480 / 8 | 128 | 4,8 | 6,60 | 7,80 |

| 480 / 9 | 143 | 4,8 | 7,43 | 8,63 |

| 480 / 10 | 158 | 4,8 | 8,25 | 9,45 |

| 480 / 11 | 173 | 4,8 | 9,08 | 10,28 |

| 480 / 12 | 188 | 4,8 | 9,9 | 11,1 |

| 480 / 13 | 203 | 4,8 | 10,73 | 11,93 |

| 480 / 14 | 218 | 4,8 | 11,55 | 12,75 |

| 560 / 4 | 94 | 5,6 | 3,30 | 4,70 |

| 560 / 5 | 114 | 5,6 | 4,13 | 5,52 |

| 560 / 6 | 134 | 5,6 | 4,95 | 6,35 |

| 560 / 7 | 155 | 5,6 | 5,78 | 7,18 |

| 560 / 8 | 175 | 5,6 | 6,60 | 8,00 |

| 560 / 9 | 196 | 5,6 | 7,43 | 8,83 |

| 560 / 10 | 216 | 5,6 | 8,25 | 9,65 |

| 560 / 11 | 237 | 5,6 | 9,08 | 10,44 |

| 560 / 12 | 257 | 5,6 | 9,9 | 11,26 |

| 560 / 13 | 278 | 5,6 | 10,73 | 12,08 |

| 560 / 14 | 298 | 5,6 | 11,55 | 12,09 |

| 640 / 4 | 124 | 6,4 | 3,30 | 4,90 |

| 640 / 5 | 151 | 6,4 | 4,13 | 5,73 |

| 640 / 6 | 178 | 6,4 | 4,95 | 6,55 |

| 640 / 7 | 204 | 6,4 | 5,78 | 7,38 |

| 640 / 8 | 231 | 6,4 | 6,60 | 8,20 |

| 640 / 9 | 258 | 6,4 | 7,43 | 9,03 |

| 640 / 10 | 285 | 6,4 | 8,25 | 9,85 |

| 640 / 11 | 311 | 6,4 | 9,08 | 10,67 |

| 640 / 12 | 338 | 6,4 | 9,9 | 11,49 |

| 640 / 13 | 365 | 6,4 | 10,73 | 12,31 |

| 640 / 14 | 391 | 6,4 | 13,13 | 13,13 |

| 720 / 4 | 160 | 7,2 | 3,30 | 5,10 |

| 720 / 5 | 194 | 7,2 | 4,13 | 5,93 |

| 720 / 6 | 227 | 7,2 | 4,95 | 6,75 |

| 720 / 7 | 261 | 7,2 | 5,78 | 7,58 |

| 720 / 8 | 295 | 7,2 | 6,6 | 8,40 |

| 720 / 9 | 329 | 7,2 | 7,43 | 9,23 |

| 720 / 10 | 363 | 7,2 | 8,25 | 10,05 |

| 720 / 11 | 396 | 7,2 | 9,08 | 10,87 |

| 720 / 12 | 430 | 7,2 | 9,9 | 11,69 |

| 720 / 13 | 464 | 7,2 | 10,73 | 12,51 |

| 720 / 14 | 498 | 7,2 | 11,5 | 13,33 |

Options

Wall support for conveyor

Conveyor support is attached to silo wall. It has a maximum load of 600kg and it’s height can be fine adjusted 6cm.

Catwalks

Grain level monitor

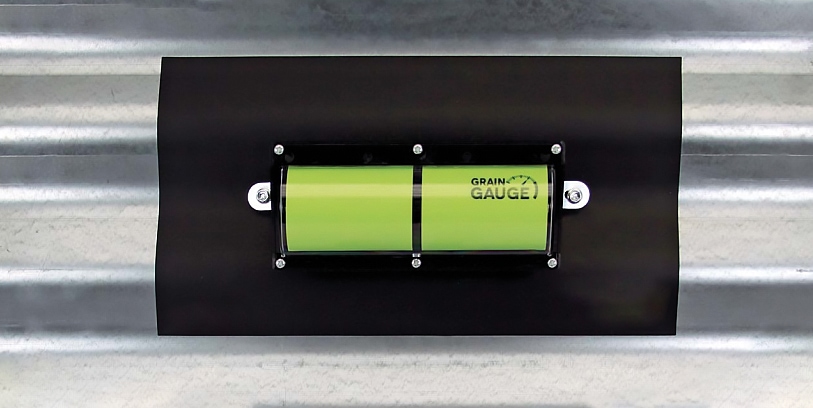

You can get a mechanic and maintenance free grain level monitor for silo. It’s proven and cost effective method to accurately monitor the levels of material in your silo. As the material in your bin reaches the grain level monitor, it turns the color from black to green – even glowing in the dark! You can install multiple level monitor devices along the silo wall at key levels.

Discharge augers and conveyors

There are different augers and conveyors available for silo discharging and grain transfer.