K series mobile dryer

Cost-effective and efficient grain drying

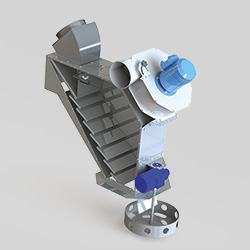

K series mobile dryers by Mepu are cost-effective, efficient, and quickly deployable warm air-drying units. The mobile dryer is easily movable from one place to another.

The advantages of the easy-to-use and reliable mobile dryer as compared to conventional stationary silo dryers include savings in costs, quick commissioning, drying efficiency and dryer height.

Efficient under demanding circumstances

The high-tech mobile dryer offers uniform drying efficiency even under demanding circumstances and allows energy-efficient drying of wet grain as well. The mobile dryer is suitable for drying several types of grain and small seeds. The feeding apparatus is equipped with a frequency converter.

OPTIONS

- Channel aspirators

- Cyclone systems for elevator and pre-cleaner

- Grain space increase

- Step extension

- Motored dividers

Features

ELEVATOR

A powerful bucket elevator is a silent and reliable elevator equipped with a direct drive motor for efficient and gentle grain transfer.

PRE-CLEANER, SPREADER AND BOTTOM ASPIRATOR

All models are equipped with a pre-cleaner powered by a dedicated motor, which ensures a high-quality outcome. The spreader distributes the grain evenly over the entire grain bin. The bottom aspirator removes dust and humidity.

SAMPLING UNIT AND BOTTOM THROUGHS

The sampling unit facilitates supervision over the drying process.

The steep-sided bottom through ensures closed circulation of the grains under any conditions. Dust and humidity are removed during the drying process by the bottom aspirator. The grain in the bottom through flows to the auger, which is easy to clean thanks to the opening bottom.

EXHAUST AIR CHANNEL OUTPUTS

Exhaust air channel outputs (standard) M 180k – M 205k Ø500mm, M 240k – M 420k Ø630mm.

GRAIN BIN

Wet grain swells when warmed up. As the drying proceeds, the grain volume reduces considerably. The grain bin is optimized to function under any conditions. The bin is made of hot galvanized steel.

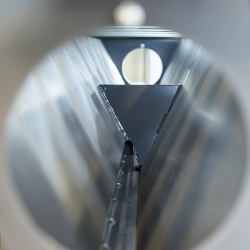

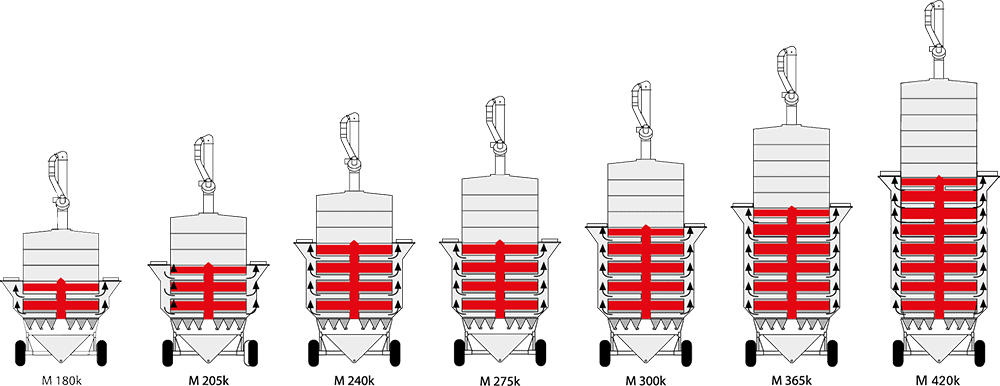

DRYING CELLS

The drying cells are so-called ridge beam cells, of which there are two in parallel. Warm air is blown into a heating channel between the drying cells, resulting in minimal heat loss. Shutters designed for drying of partial batches are standard equipment in all models. The shutters provide for efficient drying of partial batches. Fully galvanized structure.

FEEDING APPARATUS

All models are equipped with adjustable speed feed rollers (6pcs) with flaps mounted underneath. Steep-angled feed troughs ensure an even drying process and reliable circulation under any circumstances. The dryer is also suitable for small seed drying. Recycle speed is adjusted variably with a frequency inverter.

DRYING FURNACE AND CONTROL

Energy-efficient furnaces by Mepu produce enough heat and air capacity even under challenging circumstances.

The electrical equipment and automatic systems are installed at the factory. An accurate and conveniently adjustable electronic drying thermostat with a digital display ensures efficient control. The dryer is ready for use after connecting the machine to the power supply and installation of the oil burner lines to the oil tank.

FRAME

The drying equipment is installed on a sturdy steel beam frame. If necessary, the dryer can be relocated. During the drying process, the dryer’s support legs (standard equipment) must be lowered. A detachable drawbar saves space, rendering the dryer even more convenient.

| MODEL | M 180K | M 205K | M 240K | M 275K | M 300K | M 365K | M 420K |

|---|---|---|---|---|---|---|---|

| Width (transportation / operation) [m] | 3,14 / 3,87 | 3,14 / 3,87 | 3,14 / 3,87 | 3,14 / 3,87 | 3,14 / 3,87 | 3,14 / 3,87 | 3,14 / 3,87 |

| Transportation width [m] | 6,23 | 6,23 | 6,23 | 6,23 | 6,23 | 6,23 | 6,23 |

| Transportation height [m] | 4,25 | 4,25 | 4,25 | 3,85 | 3,85 | 3,85 | 3,85 |

| Operational length (max / min) [m] | 8,08 / 6,85 | 8,08 / 6,85 | 8,08 / 6,85 | 8,08 / 6,85 | 8,08 / 6,85 | 8,08 / 6,85 | 8,08 / 6,85 |

| Equipment height (to cover) [m] | 4,3 / 4,6 | 4,8 / 5,1 | 5,5 / 5,8 | 6,3 | 6,8 | 8 / 9,7 | 9,7 |

| Elevator height [m] | 8,25 | 8,75 | 9,5 | 10 | 10,5 | 11,75 | 13,5 |

| Grain volume [m3] | 16,3 | 18,4 | 21,6 | 25,1 | 27,2 | 33,9 | 39,4 |

| Min. drying batch [m3] | 3,5 | 6,2 | 6,2 | 6,2 | 6,2 | 6,2 | 12 |

| Equipment weight [t] | 5 | 6 | 7 | 7,5 | 8 | 8,5 | 9,4 |

| Furnace recommendation [kW] | 250 / 300 | 250 / 400 | 310 / 400 | 400 | 500 | 500 | 500 |

| Fuse size [A] | 25 | 32 | 32 | 32 | 50 | 50 | 50 |

| Electric power [kW] | 11 / 17.75 | 15 / 17.75 | 21.25 | 22 | 25.55 | 26.55 | 27.55 |