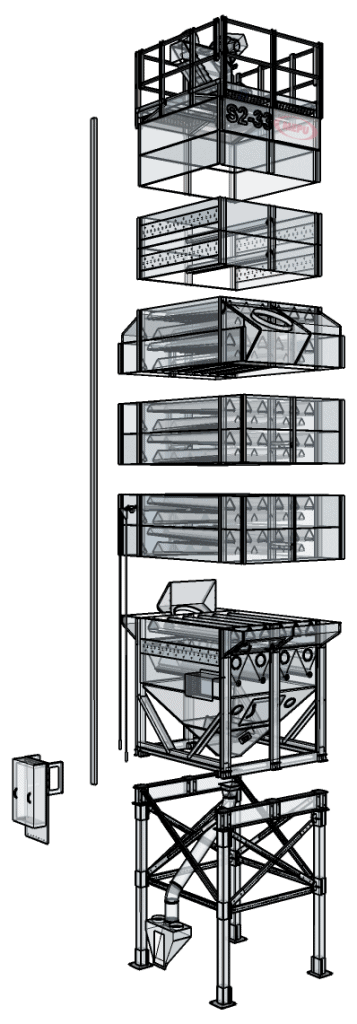

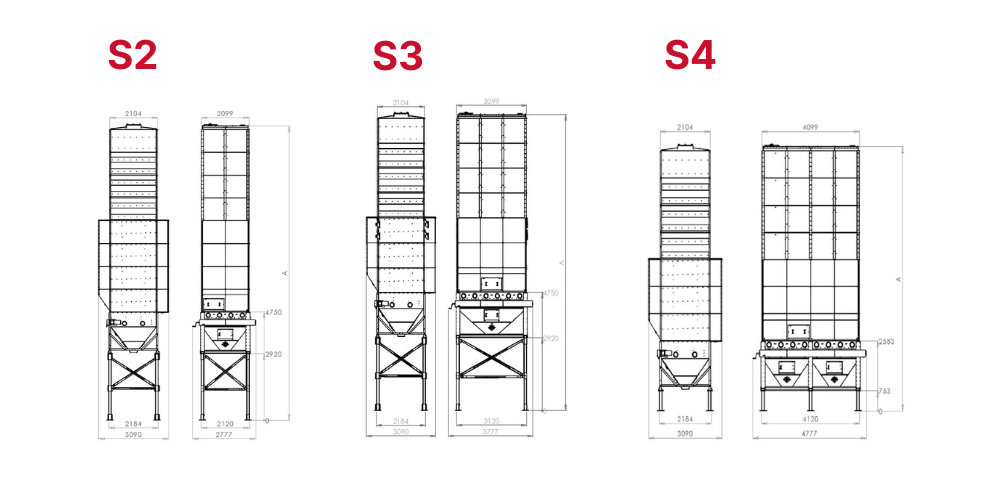

S series batch dryer

High-quality and efficient grain drying

The stationary S series dryers by Mepu dry the grain in a gentle, energy-efficient, and reliable even under challenging circumstances. Grain batch humidity does not affect the outcome, since the grain is dried by circulating it through drying cells and equalizing the grain humidity in the top bin so many times that the entire grain batch is fully dry.

S series dryers are based on the same high-quality technology as Mepu’s high-power continuous flow dryers. In addition to advanced drying technology, reliability and ease of use have been emphasized in the dryer design.

options

- Dust removal packages for the elevator

- Logic control centres, tailored according to the client’s requirements

- A low base with a bottom auger for tight spaces

- Biogas and direct-fire gas furnaces available as heat sources

- Heat insulation

Flexibility and Efficiency for Your Farm's Needs

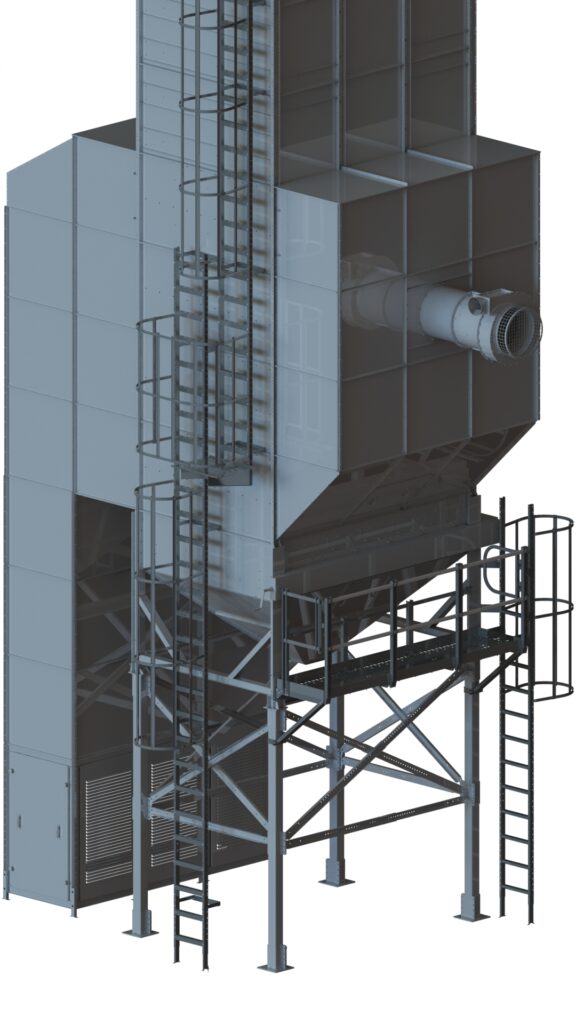

The renewed S-Series batch dryer sets a new standard for grain drying efficiency and usability. This state-of-the-art dryer is now 50% faster to install and features improved maintenance capabilities. The maintenance platform for the feeder and grain silo roof enhances work safety and speeds up servicing tasks. The platforms are equipped with grated surfaces, significantly reducing the risk of slipping.

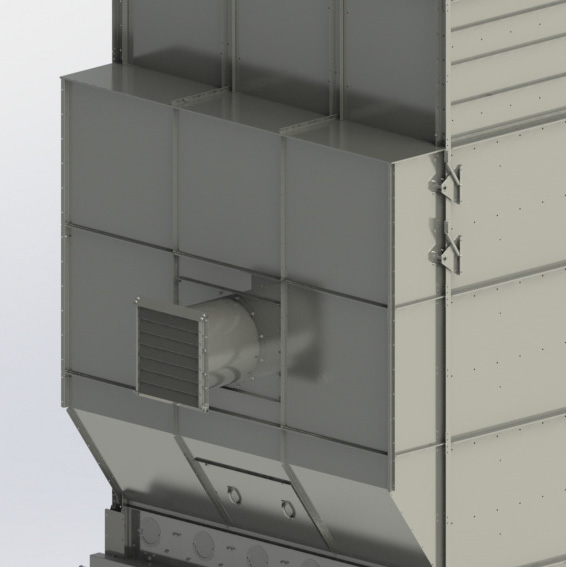

The dryer offers versatile and flexible air intake options. Air can be drawn in from either the side or the bottom, ensuring efficient use of available space.

The air exhaust can be directed either upward or to the side, increasing installation possibilities and making it easier to adapt the dryer to various setups.

Thanks to its modular design, the S-Series is easy to customize according to the available space and specific customer requirements. It’s also an excellent choice for upgrading older drying systems, bringing modern flexibility and efficiency to existing structures.

Benefits of the S-Series

- Quick to install

- Easy access to maintenance points thanks to maintenance platforms

- Efficient grain drying

- Modular design, easily customizable

- Flexible options for air intake and exhaust points

- Redesigned spreading plate ensuring even drying results and uniform distribution in the grain silo

- Upgraded pre-cleaner with a powerful 4kW vacuum

- Flexible automation options tailored to customer needs

Features

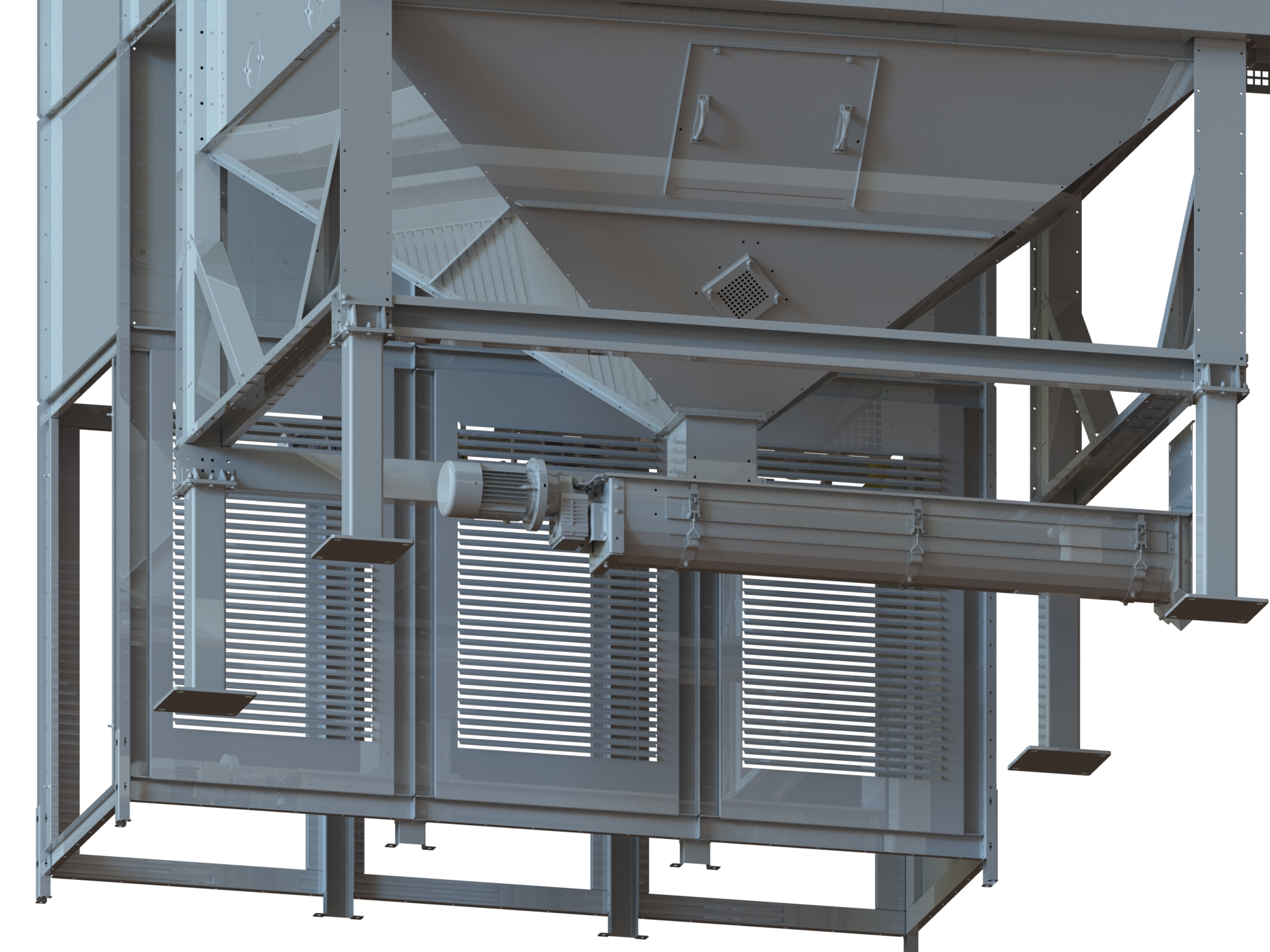

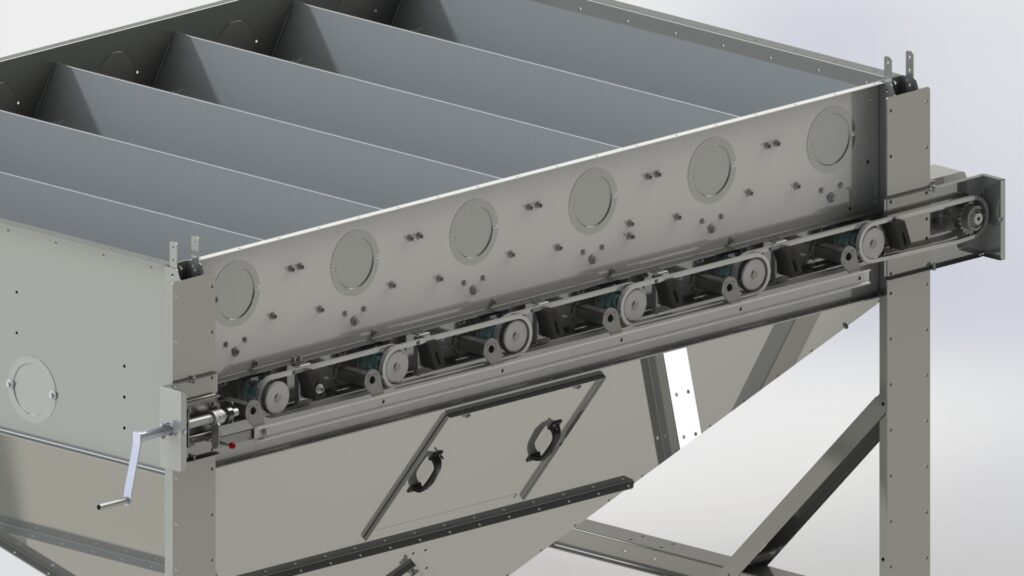

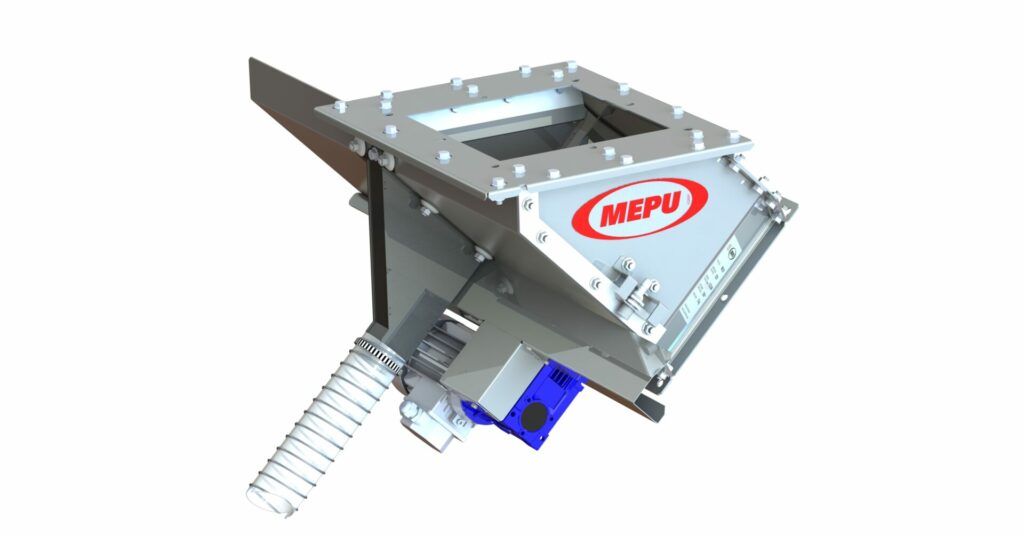

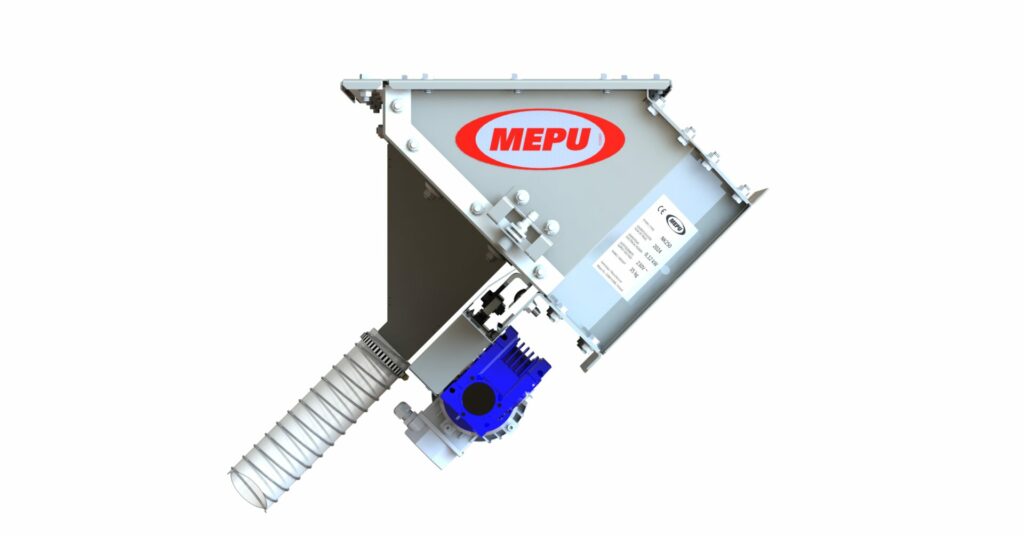

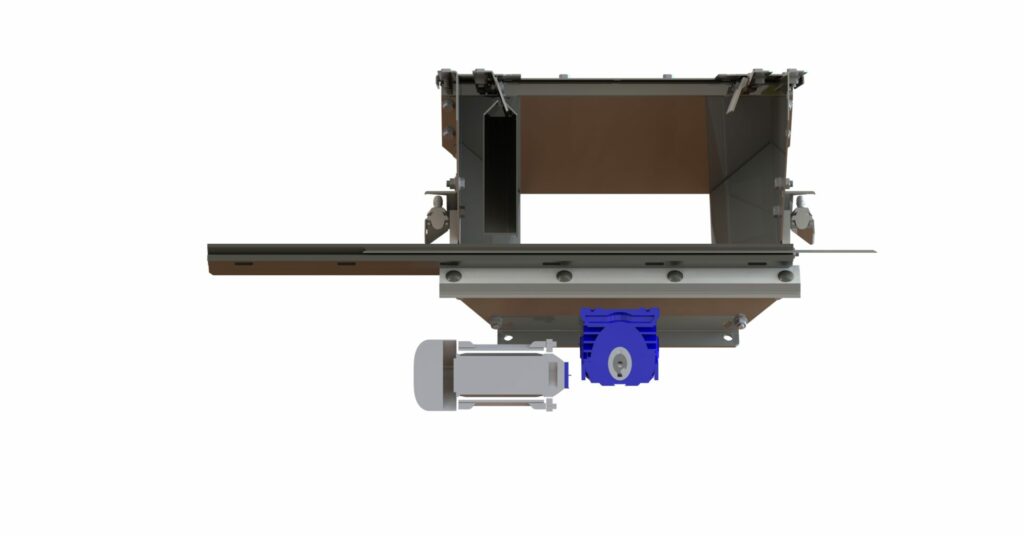

BOTTOM CONE AND AUGER CONEYOR

Steep-sided and smooth-walled cone bottoms ensure that the grain always flows to the bottom screw. The cone bottom is easy to clean through large maintenance hatches. The reliable screw conveyor efficiently transfers the grain.

There is a generous gap between the screw and the bottom trough, ensuring gentle grain transfer. The M-series features a bottom auger powered by a gear motor. The auger is available in two different capacities: 60 tons and 80 tons.

FEEDING APPARATUS

The adjustable-speed rotating feed rollers ensure even grain circulation in all conditions. The hopper doors, which can be opened, make cleaning the dryer quick and easy.

The feeding apparatus is easy to clean through service hatches on the side and the openable hopper doors. With the optional service platform available for the M-series, you can enhance safety and speed up maintenance tasks. All service points are located on the same side of the feed device.

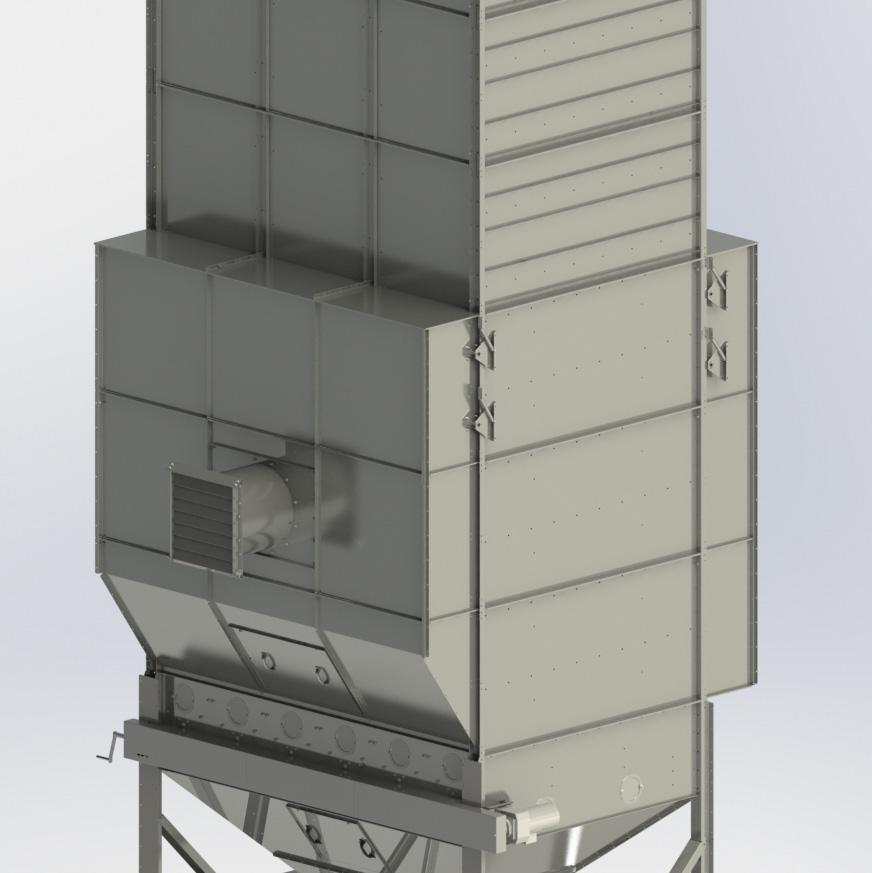

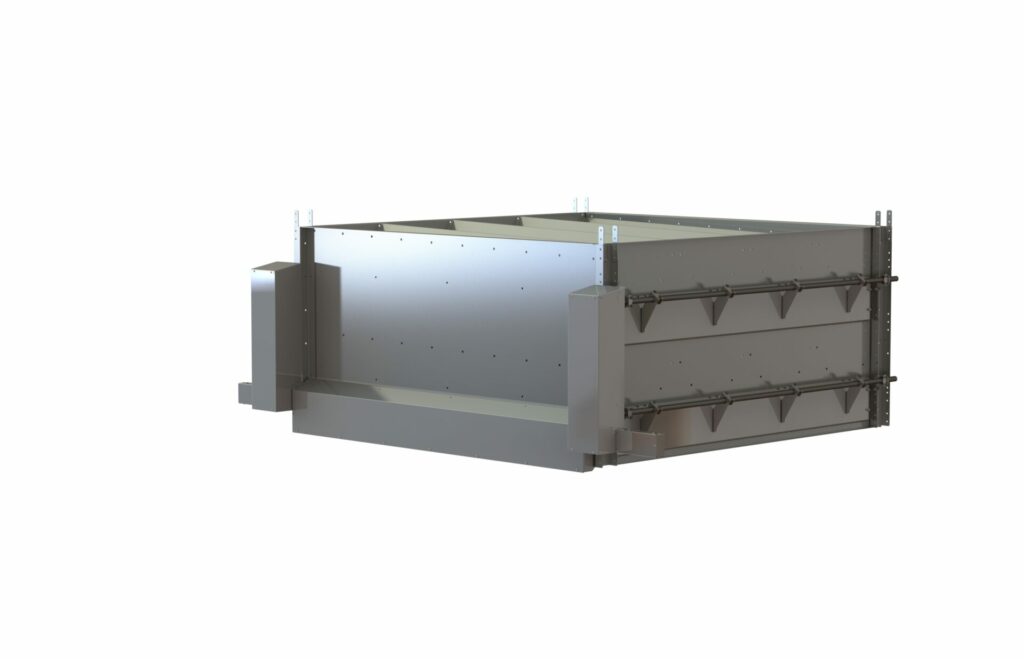

AIR DUCTS

The inner surface of the air ducts is smooth, and the lower corner of the exhaust air casing is at a 50° angle, minimizing grain and dust buildup on the surfaces. Grain that flies into the exhaust air casing is returned to the feed device, thus reducing the need for cleaning the air ducts. Large service hatches make maintenance easy and quick.

The air ducts are available in two different depths: 500 mm or 1000 mm.

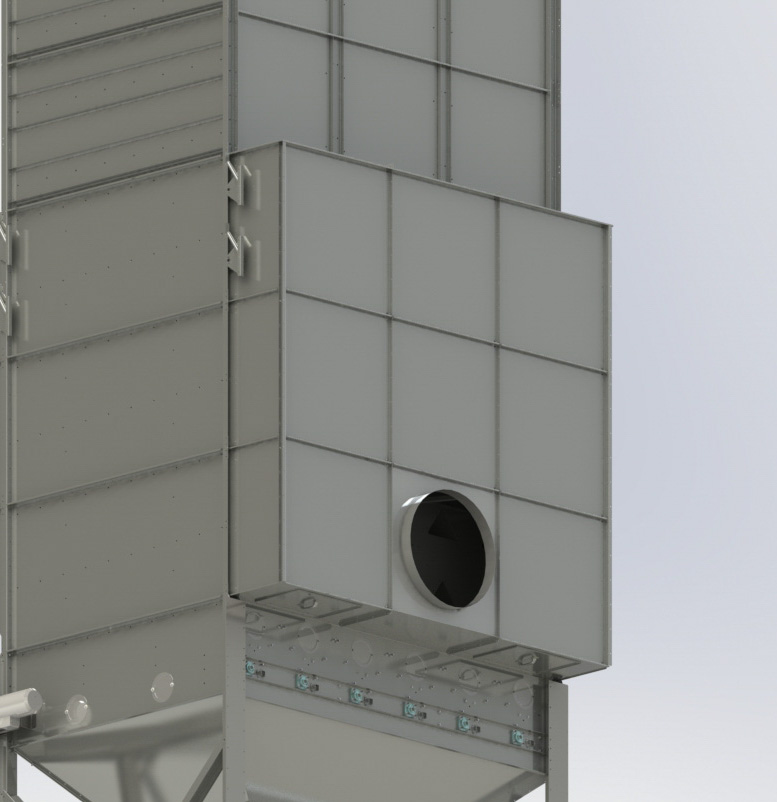

INTAKE AND OUTLET DUCT

Intake

The Mepu M-series dryer offers two different types of inlet ducts, which can be selected according to your needs.

Outlet duct

The outlet connection location can be chosen either to the side or upward from the air casing.

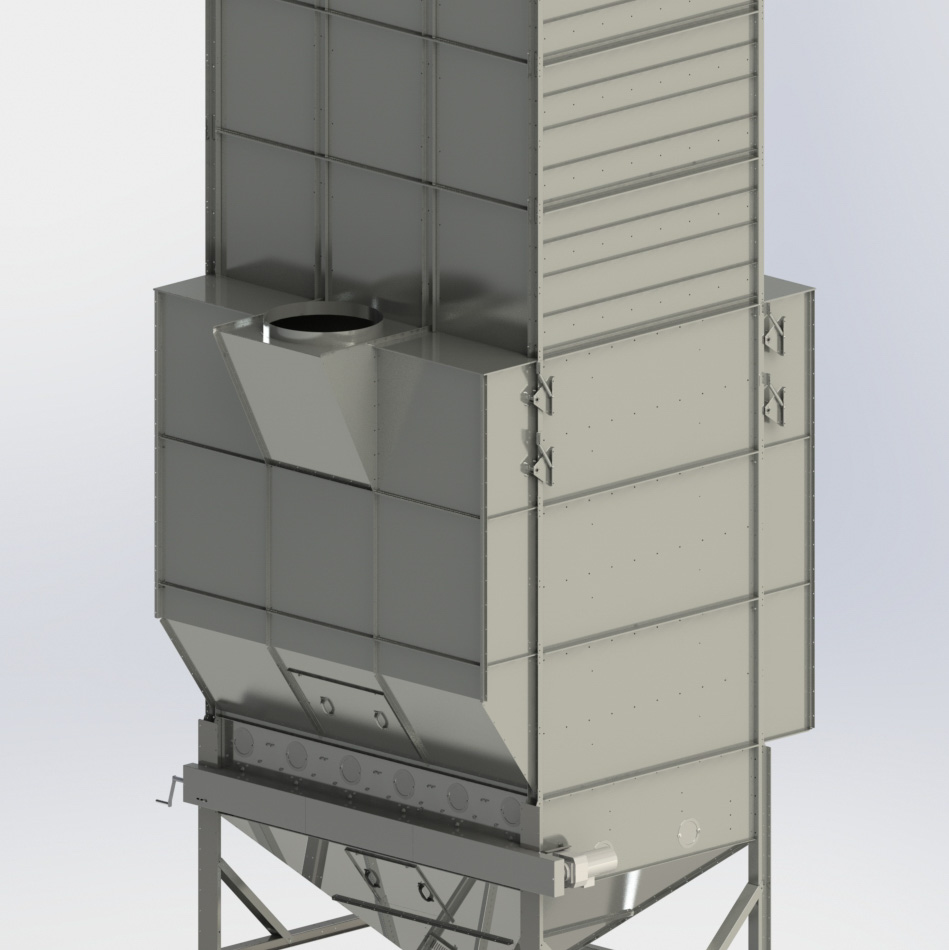

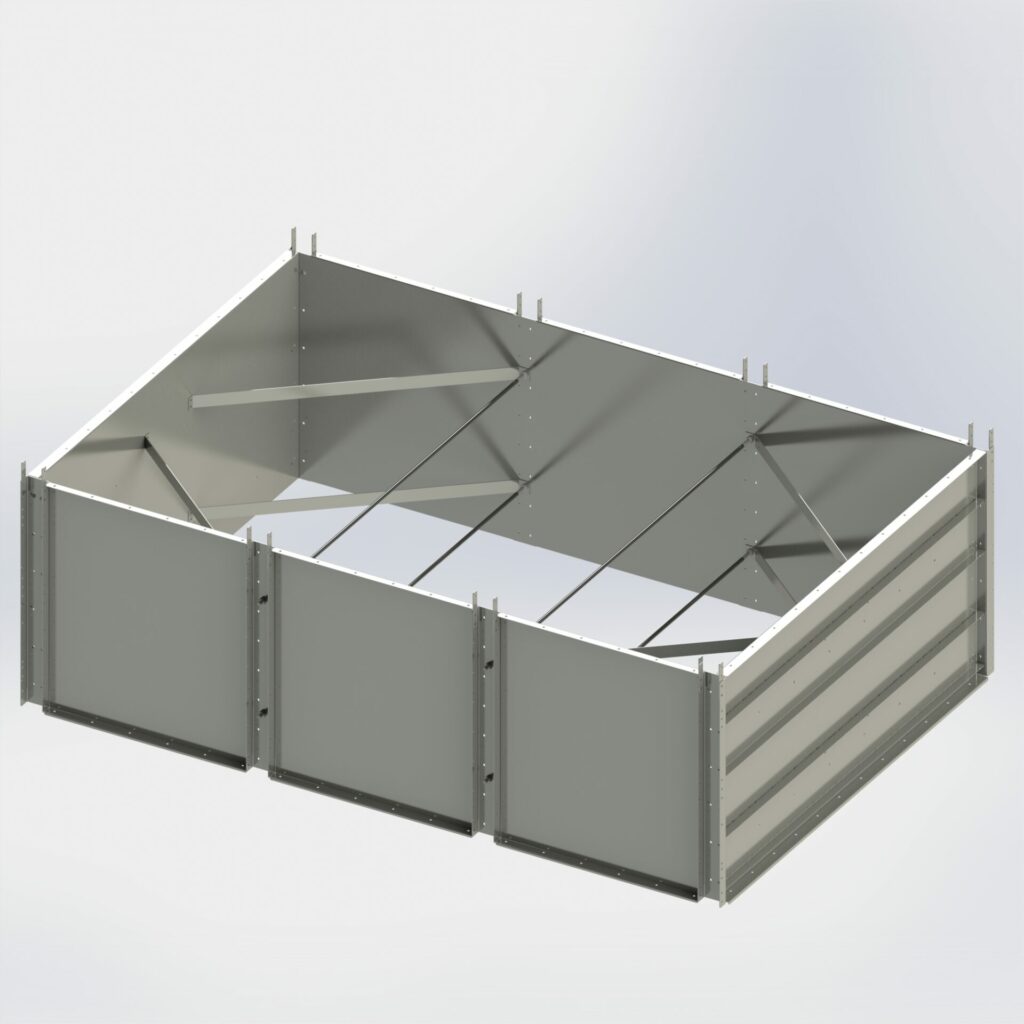

GRAIN BIN

The durable and smooth-surfaced grain chamber ensures the flow of grain into the drying section even in wet conditions.

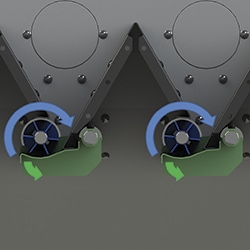

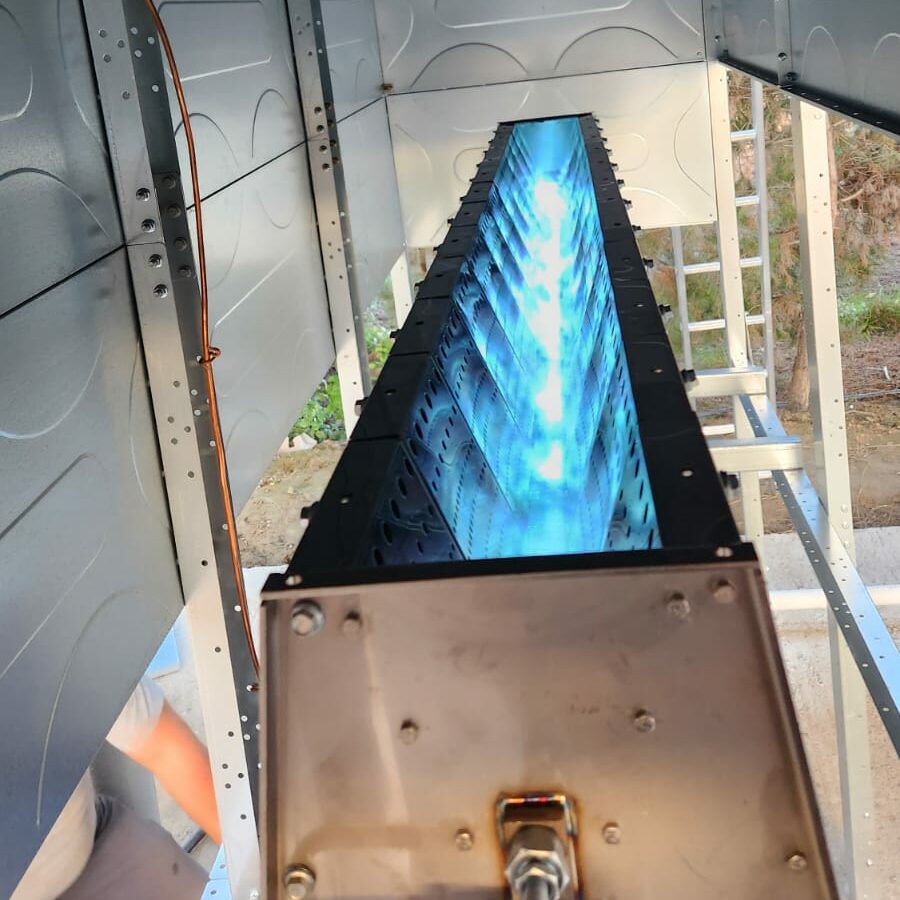

DRYING CELLS

The wedge-profile drying cell ensures efficient mixing of air and grain, resulting in a consistent and energy-efficient drying outcome. The smooth interior surfaces of the drying cell keep it clean, making maintenance quick and effortless.

The S-Series dryer is available with either a motorized or manual drying cell closure mechanism, enabling partial batch drying.

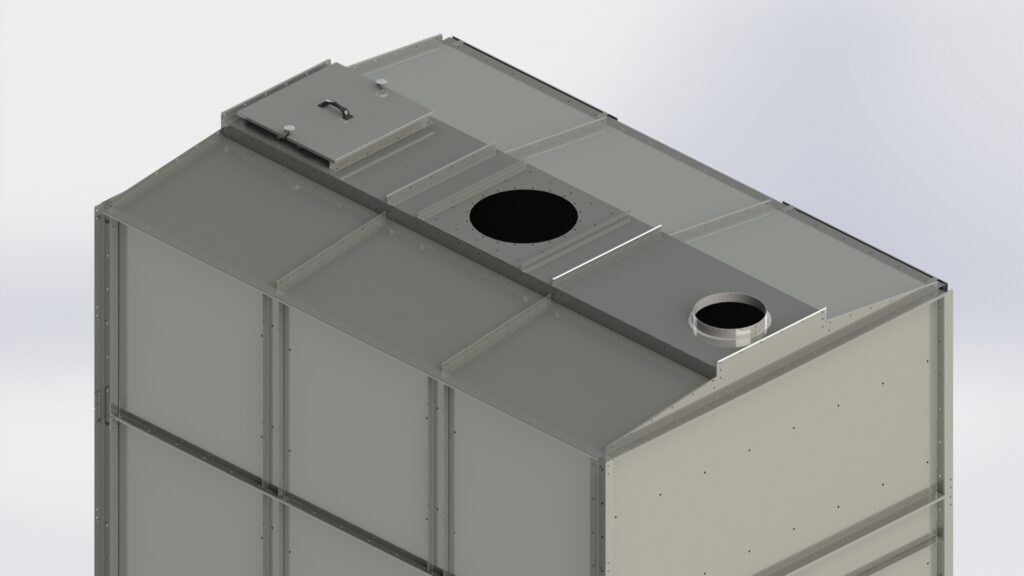

PRE-CLEANER WITH SPREADER

A pre-cleaner equipped with a spreading disc evenly distributes the grain into the grain tank, efficiently fills the tank, and cleans the grain from debris and dust.

ELEVATOR

The efficient and quiet cup elevator ensures fast filling and emptying of the dryer. The elevator's upper section features a 3-way divider, allowing the grain flow to be directed either into the dryer or out of the dryer.

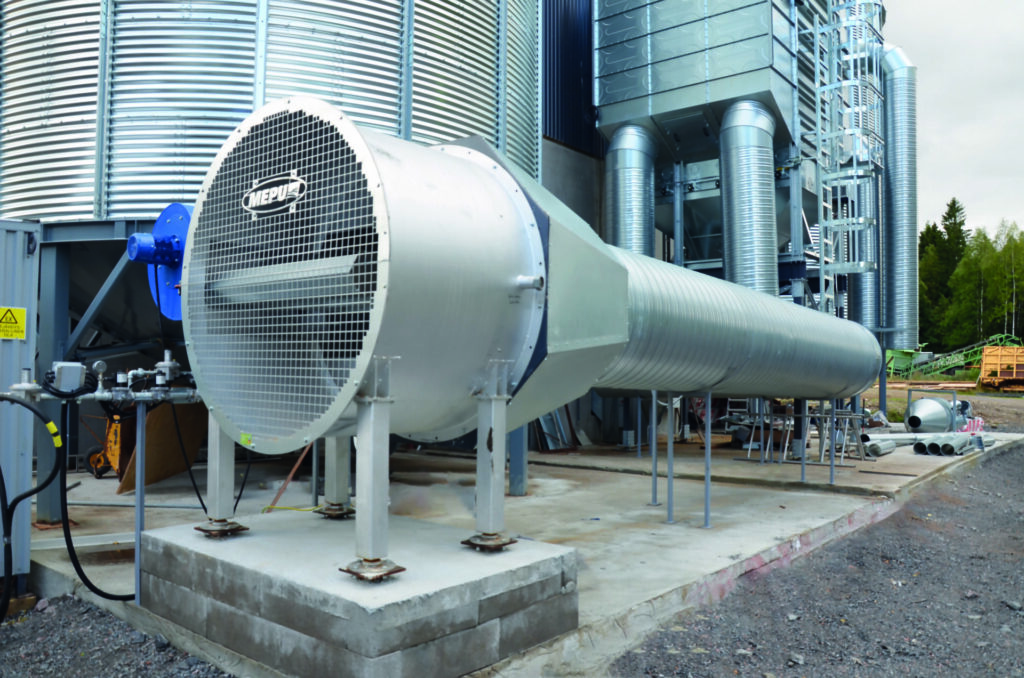

AXIAL FANS

The high-efficiency axial fans ensure a cost-saving drying result.

HEAT SOURCE

Tehokkaat yli- ja alipaineuunit takaavat kustannuksia säästävän kuivaustuloksen. Lämmönlähteenä voidaan käyttää myös Mepun biouunia tai suorakaasupolttimia.

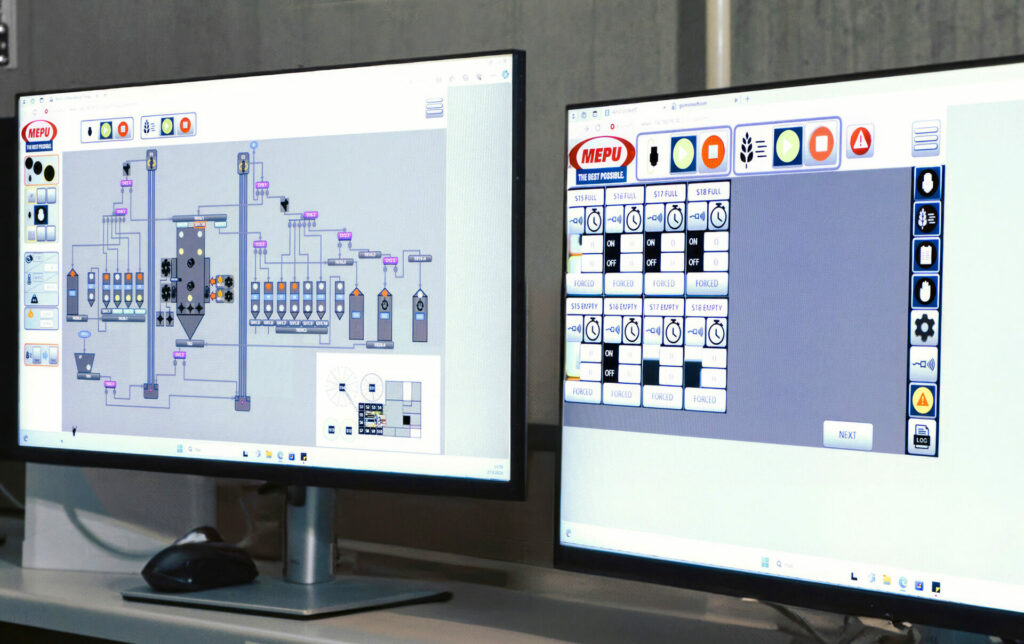

CONTROL PANEL

The standard equipment includes a simple and intuitive control panel, making the dryer extremely easy to use. A versatile and customizable automation solution is also available, tailored to customer needs.

SAMpling device

With the Mepu NK250 sampling device, you can automatically take samples within the programmed time interval during the unloading phase. The sampling device includes funnels for sampling in 4 mm, 6 mm, and 8 mm sizes. Please note that the NK250 does not operate in the dryer without the Mepu AUTO control panel.

GAS BURNER CASING

Line burner's casing

| S2-sERIES | S2-18 | S2-22 | S2-32 | S2-35 | S2-38 |

|---|---|---|---|---|---|

| Equipment height A [m] * | 10,0 | 11,0 | 14,0 | 15,0 | 16,0 |

| Water volume [m³] | 18,4 | 22,4 | 32,4 | 35,4 | 38,4 |

| Grain volume max. [m³]** | 16,1 | 20,1 | 30,1 | 33,1 | 36,1 |

| Drying section volume [m³] | 9,0 | 9,0 | 15,0 | 18,0 | 21,0 |

| Buffer section volume [m³] | 8,0 | 12,0 | 16,0 | 16,0 | 16,0 |

| Drying cell / Buffer zone [pcs] | 3 - 2 | 3 - 3 | 5 - 4 | 6 - 4 | 7 - 4 |

| Elevator min. height [m]* | 13,2 | 14,2 | 17,2 | 18,2 | 19,2 |

** Grain volume calculated with wheat, 18% moisture content. When drying from high moisture levels the grain expands thus lowering the max filling volume. Values are theoretically calculated and may vary depending on local conditions and cereal properties

| S3-sERIES | S3-33 | S3-38 | S3-48 | S3-53 | S3-57 | S3-62 |

|---|---|---|---|---|---|---|

| Equipment height A [m] * | 11,0 | 12,0 | 14,0 | 15,0 | 16,0 | 17,0 |

| Water volume [m³] | 33,3 | 37,8 | 48,2 | 52,7 | 57,2 | 61,7 |

| Grain volume max. [m³]** | 29,9 | 34,4 | 44,8 | 49,3 | 53,8 | 58,3 |

| Drying section volume [m³] | 13,5 | 18,0 | 22,5 | 27,0 | 31,5 | 36,0 |

| Buffer section volume [m³] | 17,7 | 17,7 | 23,6 | 23,6 | 23,6 | 23,6 |

| Drying cell / Buffer zone [pcs] | 3 - 3 | 4 - 3 | 5 - 4 | 6 - 4 | 7 - 4 | 8 - 4 |

| Elevator min. height [m]* | 14,5 | 15,5 | 17,5 | 18,5 | 19,5 | 20,5 |

** Grain volume calculated with wheat, 18% moisture content. When drying from high moisture levels the grain expands thus lowering the max filling volume. Values are theoretically calculated and may vary depending on local conditions and cereal properties

| S4-sERIES | S4-50 | S4-72 | S4-78 | S4-84 | S4-96 | S4-108 |

|---|---|---|---|---|---|---|

| Equipment height A [m] * | 9,8 | 12,8 | 13,8 | 14,8 | 16,8 | 18,8 |

| Water volume [m³] | 50,4 | 72,2 | 78,2 | 84,2 | 96,2 | 108,2 |

| Grain volume max. [m³]** | 45,8 | 67,6 | 73,6 | 79,6 | 91,6 | 103,6 |

| Drying section volume [m³] | 24,0 | 30,0 | 36,0 | 42,0 | 54,0 | 66,0 |

| Buffer section volume [m³] | 23,6 | 39,4 | 39,4 | 39,4 | 39,4 | 39,4 |

| Drying cell / Buffer zone [pcs] | 4 - 3 | 5 - 5 | 6 - 5 | 7 - 5 | 9 - 5 | 11 - 5 |

| Elevator min. height [m]* | 13,8 | 16,8 | 17,8 | 18,8 | 20,8 | 22,8 |

** Grain volume calculated with wheat, 18% moisture content. When drying from high moisture levels the grain expands thus lowering the max filling volume. Values are theoretically calculated and may vary depending on local conditions and cereal properties

Videos

READYMADE-grain dryer

Since 1983, Mepu has been constructing ready-to-use batch dryers according to customers' wishes.

Mepu's READYMADE concept is available for all dryers manufactured by Mepu, where the dryer is delivered electrified and nearly ready for installation. Motors and cable harnesses with connectors are pre-installed. Pre-assembled drying units, grain bins, and the cover with railings expedite the construction process. The heater, automation, and all essential components for commissioning are included in Mepu READYMADE deliveries.

Modern Drying Technology

Mepu's drying technology is energy-efficient, reducing operational costs. The heat sources used for drying ensure a high-efficiency ratio. You can choose between the BASIC/SEMI-automatic control panel or the AUTO-automatic control panel with continuous moisture measurement and remote control. The moisture measurement is accurate and reduces the costly risk of over-drying or under-drying, achieving the desired moisture level, rain or shine!

The variable frequency drive for the axial fans reduces electricity consumption, and the stepless adjustment of air volume optimizes the drying air temperature. With the optional insulation package, energy consumption is low, drying is more efficient, and you can save up to 10-20% on energy costs.

Mepu READYMADE dryers do not require special transportation. Construction and commissioning happen quickly. Resale value is well-known to remain high. Mepu dryers are known for their long service life and low maintenance and spare parts costs.